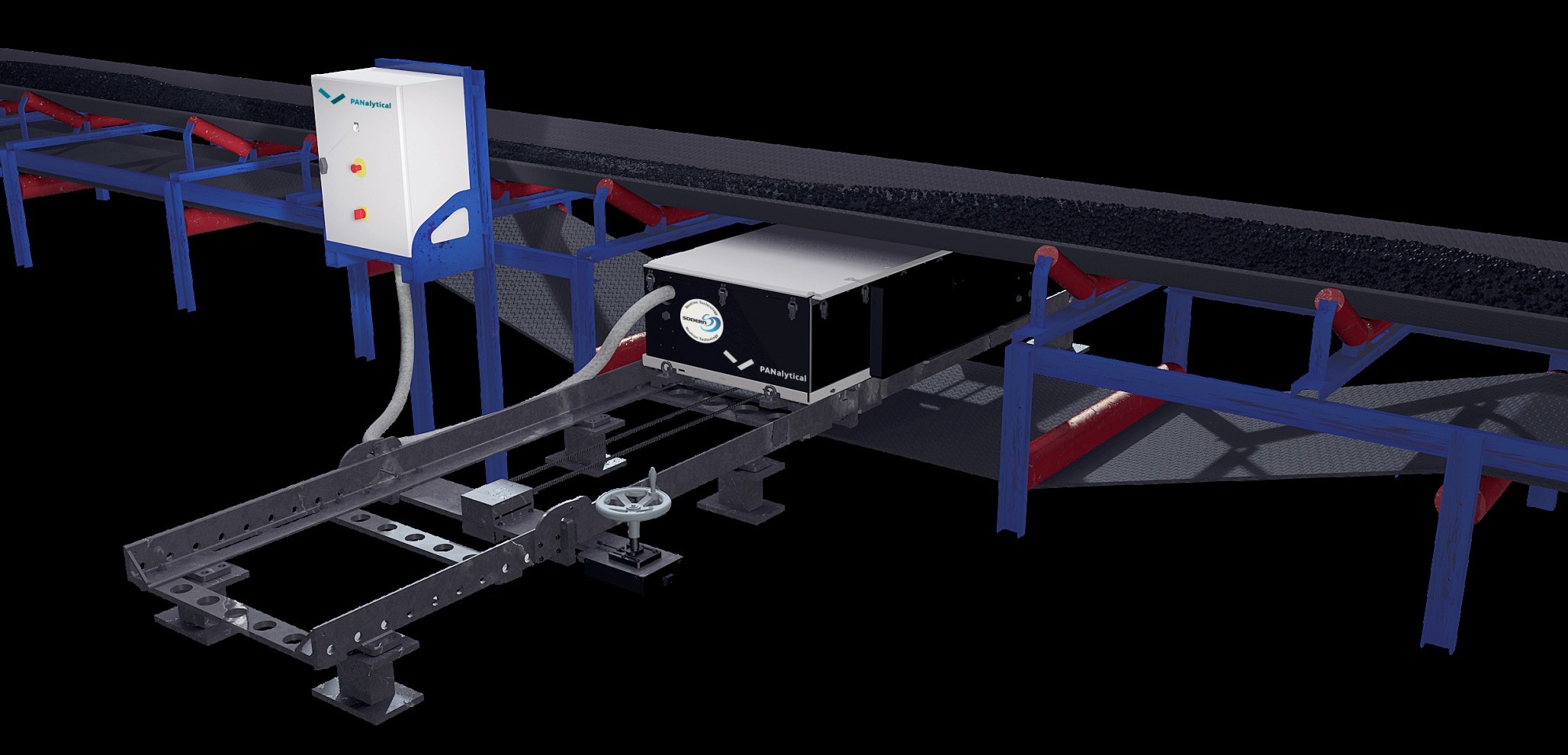

The Panalytical CNA, featuring Sodern Neutron technology, is the next generation of the world’s most advanced on-line elemental analyzer, based on PFTNA, pulsed fast and thermal neutron activation, technology. The instrument is available in two configurations – the classical CNA “through the analyzer” configuration and the more recent CNA3 , where the belt passes over the analyzer.

2 CNA3 Configuration - the belt passes over the analyzer

2 CNA3 Configuration - the belt passes over the analyzer

The classical CNA configuration is used in cement and related industries with modest size belts (< 2 meter), well controlled particle size, and the potential for layered material. The CNA3 is more applicable for mining applications with large rock size and wide conveyor belts.

Both configurations provide benefits by their ability to measure the bulk of the material passing on the belt and report the composition, typically two minute averages, in real time.

While the specific benefits are industry specific, in general the information from the CNA provides:

- Mine Feedback – real time results to guide mining operations

- Sorting – to provide information to separate material based on composition

- Mixing – blend mine or stockpile streams to meet product specifications

- Process feed forward – enable process controls to anticipate material changes

- Process feedback – provide real time trends to monitor process quality and stability.

Key Features

The key features of Panalytical CNA are:

- On-off electric neutron source – safe and flexible operation

- Automated radiation protection system (ARPS)

- Modular design for minimum downtime during installation

- Built-in direct link diagnostics program, ensuring optimum operation and uptime

- Constant neutron flux eliminates expensive and inconvenient periodic on-site calibration

Industries

There are Panalytical CNA models dedicated to specific industries. These include:

- CNA Pentos-Cement – Stockpile and Raw Mix Control

- CNA Nickel and CNA3 Nickel – Stockpile and Process Control

- CNA3 Iron – Mining and Stockpile Feedback

- CNA3 Copper – Feed sorting and mixing

- CNA3 Coal – Information for Managing Mining, Preparation, Stockpile, and End Use of Thermal and Metallurgical Coals