Mar 28 2016

Rice Earth scientists have many ways to see deep into the planet, from drilling to seismic models to simulations, and now they have a way to see deep into what comes from the depths.

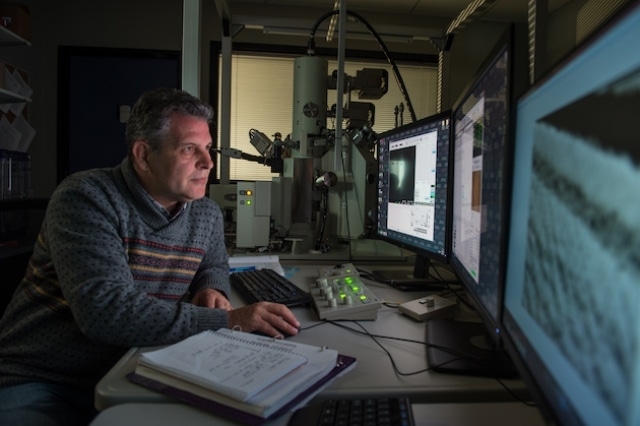

Gelu Costin monitors an experiment at the Electron Probe MicroAnalyzer. Photo by Jeff Fitlow

Gelu Costin monitors an experiment at the Electron Probe MicroAnalyzer. Photo by Jeff Fitlow

The Department of Earth Science brought a powerful new instrument online earlier this year that lets researchers view the fine structures and composition of inorganic samples. And the tool has also been of use to local industries and other academic institutions.

The field emission Electron Probe MicroAnalyzer combines the abilities of an electron microscope and sophisticated spectrometers. Installed at Keith-Wiess Geological Laboratories, it allows for the precise quantitative chemical analysis of samples for almost all of the elements on the periodic table, from beryllium to uranium. New spectroscopic capabilities will allow for the identification of very light elements like lithium in the near future, but analyses are already underway for nitrogen and carbon in crystals and glasses.

Installation of the new microprobe, a state-of-the-art JEOL JXA 8530F Hyperprobe, drew geologist Gelu Costin to Rice last year. Costin joined the department as a staff scientist to manage the scope, which he said is the only one of its kind at a university in the southwest United States.

“This is a new invention, field emission on a microprobe,” Costin said.

The instrument bombards samples of rock or other inorganic materials with electrons focused into a tight beam by a series of electromagnetic lenses. The beam interacts with the sample to reveal nanoscale compositional patterns as small as hundreds of nanometers, while allowing the spectrometers to quantify the object’s constituent elements.

The probe is fitted with four spectrometers to analyze elements that respond to different wavelengths and an energy-dispersive X-ray spectrometer, all of which work in a high-vacuum environment to image and provide fine analysis of samples. Soon the instrument will be fitted with a fifth spectrometer that will allow quantification of trace elements as well.

“There are not many analytical techniques that allow major- and minor-element chemistry determination down to micron and submicron scales,” said geologist Rajdeep Dasgupta, a Rice professor of Earth sciences whose experimental petrology lab simulates pressures deep in the planet to produce samples of what might be found there. “This new generation of electron microprobe gives the type of spatial resolution required to characterize some of the high-pressure experiments.

“We can now determine many minor elements, all the major elements and even some of the trace elements in solid phases and quenched glasses from high-pressure experiments,” he said.

Dasgupta said the instrument expands the range of research the university’s Earth scientists can take on. “In my group we perform experiments to figure out the behavior of minerals and rocks at extreme pressures and how they exchange elements between different phases,” he said. In the past, researchers would take samples to microprobes at Texas A&M and NASA’s Johnson Space Center to analyze them.

“We weren’t able to tackle projects that required us to do an experiment and analyze it in detail before designing the next step,” he said. “It wasn’t practically feasible to go to another institution to get one sample analyzed. Now we’re taking on more challenging projects, and we are pushing the analytical capabilities.”

The microprobe is open to all Rice researchers as well as clients from industry and other academic institutions, Costin said. “We’ve already had a few users from outside geology,” he said. “People are coming over from chemistry to study the quality of nanometer-thin silver films deposited on graphite. With our machine, they can easily check the consistency of its thickness because we know that if the composition changes on the surface, the thickness changes as well.

“People from metallurgy companies around Houston have used our facility to check the microtextures and composition of micron-scaled phases in metallurgical slugs,” he said. “And people working in the repair and testing of metallic tools in the Houston area have come to check the composition of fillings inside microcracks produced during welding. We are open to all varieties of microprobe applications, from geology to planetary, chemistry, material science and more.”