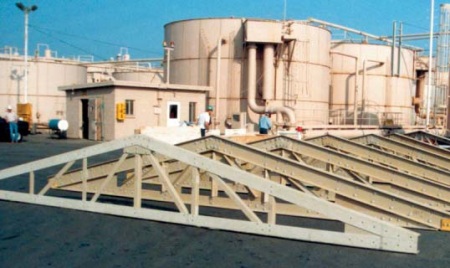

Strongwell designed, fabricated and installed a 38'-4" long x 27'-8" wide x 5' high rectangular all-fiberglass cover in order to cover and contain fumes in a sulfur pit at a Shell Oil production unit in Huntington Beach, California. The previous carbon-coated steel cover failed due to corrosion. Leaking fumes were also an air pollution problem. The challenge was the design, fabrication and installation of a vapor-tight cover to contain hydrocarbon emissions.

Solution

The cover should be able to withstand 1.0 psi pressure, 0.5 psi suction and meet UBC Zone 4 (earthquake zone building codes), assuring the customer that the cover will satisfy air pollution control regulations over the long run. The superstructure of the cover is comprised of pultruded fiberglass/vinyl ester structural shapes. The roof panels are made of 1/8" thick fiberglass plate skins that are subsequently filled with foam. Neoprene flanges and gaskets are used to make the cover vapor-tight.

Field assembly of the FRP was done adjacent to the pit and then the same was lifted into place in a single piece. The single lift of 10,000 lbs. was accomplished with FRP lifting trusses and pad eyes incorporated into the cover superstructure.

Technical Data

| Product: |

Fiberglass Sulfur Pit Cover |

| Process: |

Pultrusion |

| Materials: |

EXTREN® Series 625 fiberglass reinforced vinyl ester, fire retardant |

| Sizes: |

EXTREN® structural shapes:

1/4", 1/2" and 1/8" Plate

10" x 2-3/4" x 1/2" Channel

6" x 1/4" Wide flange beam

8" x 3/8" Wide flange beam

3" x 3" x 1/4" Angle

3" x 3" x 3/8" Angle

6" x 6" x 3/8" Angle

4" x 4" x 1/4" Angle

1-1/2" x 1-1/2" x 1/4" Channel

1-1/2" x 1/4" Square tube |

| For: |

Shell Oil |

About Strongwell Corporation

Strongwell Corporation is the world’s largest pultruder of fiber reinforced polymer composites. Strongwell’s FRP products were chosen as solutions in many different markets. For the mining industry, the company offers operating platforms, conveyor drip pans and platforms & walkways.

Strongwell Corporation design, manufacture, fabrication and testing of molded or pultruded fiber reinforced polymer composite products for construction, commercial and industrial applications.

Strongwell has been pultruding fiber reinforced polymer composite structural products since 1956. Today, with more than 65 pultrusion machines and 647,000 square feet of manufacturing space in three plant locations, Strongwell has unequaled capacity, versatility and flexibility to meet the needs of its customers and allied partners. All Strongwell pultruded products are made in the USA. Click here to learn how Strongwell’s pultruded products out perform traditional materials.

The company is financially strong, quality oriented, technically advanced, and customer focused. Strongwell's customers include Fortune 500 industrial and commercial firms, major architectural and engineering firms, leading contractors and distributors, and many other companies - both large and small - in a variety of markets.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.