Aluminum (Al) is a metal commonly used across a variety of applications and products such as, transportation, construction, electrical, and consumer products. This broad variation in application are a result of Al’s distinct properties: lightweight, strong, corrosion resistant, non-toxic, high electrical and thermal conductivity, as well as highly malleable.

When combined with additional metals to form aluminium-based alloys, the versatility of Al can be further enhanced. Additionally, Al can be easily recycled without degrading its desirable properties.

As a result of the metal’s varied use, many different Al grades are available. The London Metal Exchange (LME) lists specifications for two commonly used Al purities: 99.5% and 99.7%1, each having up to six inorganic impurities specified. The best technique for measuring impurities is with the ICP-OES because it can easily handle high-matrix samples, and is simple to operate.

PerkinElmer's Avio® 220 Max hybrid simultaneous ICP-OES is the perfect choice for this application. Its optical design provides exceptional light throughput – an important requirement when quickly measuring low impurity concentrations2. In addition, the Avio 220 Max ICP-OES uses a CCD detector. This simultaneously provides background and analyte measurements, which is crucial when sampling metal matrices3.

This work describes the analysis of impurities in Al at the LME specifications using the Avio 220 Max ICP-OES.

Experimental

Sample Preparation

All analyses were performed using 1% solutions of Al, simulating digests diluted 100x with 5% nitric acid (v/v). To test the accuracy, elemental spikes were added to the 1% Al solution at the levels determined by the “Special Contract Rules for High Grade Primary Aluminum” (Table 1). Calibration standards were prepared in 1% Al solutions at 0.5, 2, and 8 ppm to overcome matrix effects on the plasma; 5% HNO3 was used as a blank. Scandium (Sc) was added as an internal standard to all standards and samples.

Table 1. LME Special Contract Rules for High Grade Primary Aluminum and Associated Concentrations in Solution with 100x Dilution. Source: PerkinElmer

| Parameter |

Value |

| Nebulizer |

MEINHARD® K-1 |

| Spray Chamber |

Baffled glass cyclonic |

| RF Power |

1500 W |

| Injector |

2.0 mm ceramic |

| Plasma Flow |

8 L/min |

| Auxiliary Flow |

0.2 L/min |

| Nebulizer Flow |

0.65 L/min |

| Torch Position |

-3 |

| Sample Uptake Rate |

1 mL/min |

| Replicates |

2 |

| Plasma View |

Radial |

| Read Time |

0.2 sec |

Instrumentation

All analyses were conducted on an Avio 220 Max ICP-OES using the parameters in Table 2, and wavelengths in Table 3. The standard sample introduction components were used, as well as a torch position of -3. The selected wavelengths are interference-free.

The high sensitivity of the Avio 220 Max allowed for all analytes to be measured with a read time of 0.2 seconds, resulting in an analytical time of one minute per sample. The sensitivity of the Avio 220 Max also allowed all measurements to be taken in radial mode, reducing matrix effects caused by the Al and simplifying the analysis.

Table 2. Avio 220 Max ICP-OES Instrumental Parameters. Source: PerkinElmer

| Element |

Wavelength (nm) |

| Fe |

238.206 |

| Si |

251.614 |

| Ga |

417.207 |

| Zn |

206.200 |

| V |

292.466 |

| Mg |

285.214 |

| Cu |

327.393 |

| Sc (Int Std) |

361.383 |

Table 3. Elements and Wavelengths. Source: PerkinElmer

| |

P1020A: International Designations and Chemical Composition Limits for Unalloyed Aluminum |

GB/T 1196-2008: Unalloyed Aluminum Ingots for Remelting |

| Element |

Specification

(wt %) |

Concentration in 1%

Solution (mg/L) |

Specification

(wt %) |

Concentration

in 1%

Solution (mg/L) |

| Fe |

0.20 |

20 |

0.20 |

20 |

| Si |

0.10 |

10 |

0.10 |

10 |

| Ga |

0.04 |

4 |

0.03 |

3 |

| Zn |

0.03 |

3 |

0.03 |

3 |

| V |

0.03 |

3 |

--- |

--- |

| Mg |

--- |

--- |

0.02 |

2 |

| Cu |

--- |

--- |

0.01 |

1 |

Results and Discussion

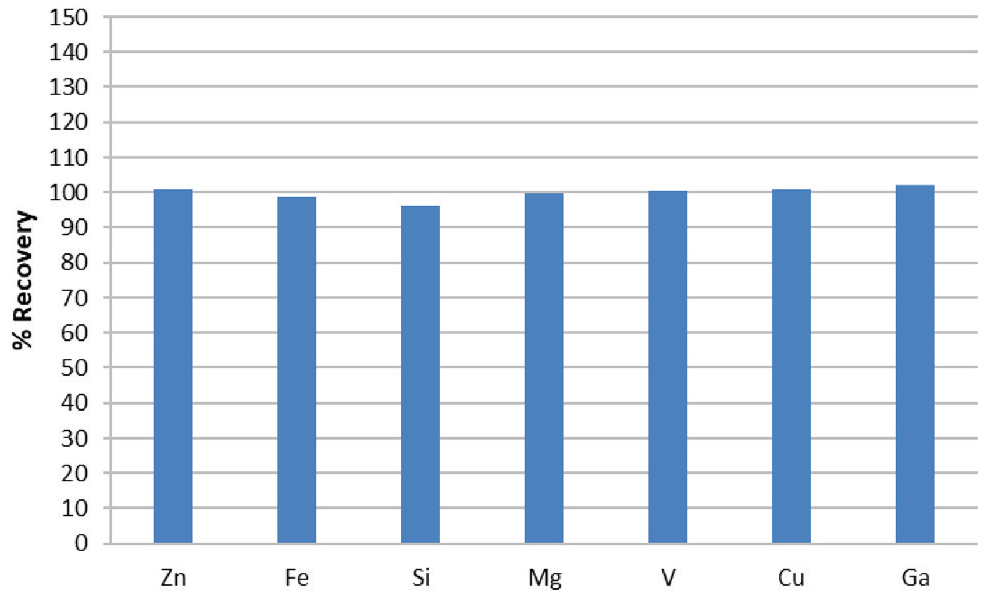

For accuracy determination, 1% Al solutions were spiked at the specification levels shown in Table 1 and measured. Figure 1 illustrates that all recoveries are within 5% of their true values, evidencing the accuracy of the methodology. With the appropriate selection of wavelengths and analytical conditions, a 1% Al matrix does not inhibit impurity analysis.

Figure 1. Analyte recoveries in 1% aluminum at the concentrations specified in LME’s Special Contract Rules for High Grade Purity Aluminum. Image Credit: PerkinElmer

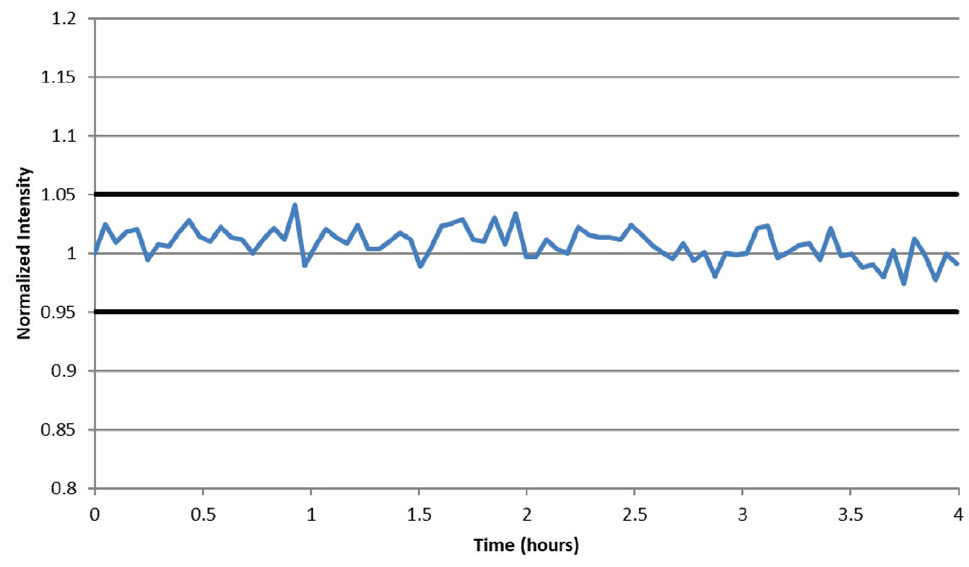

Once the accuracy had been determined, stability was assessed. One-percent aluminum samples were analysed over four hours, with a one-minute rinse between samples, and monitoring the internal standard signal. Stability results (Figure 2) show signal variation of less than 4%. This demonstrates the excellent stability of the system in the presence of a high-matrix sample.

Figure 2. Internal standard (Sc) stability over a four-hour analysis of 1% Al. Image Credit: PerkinElmer

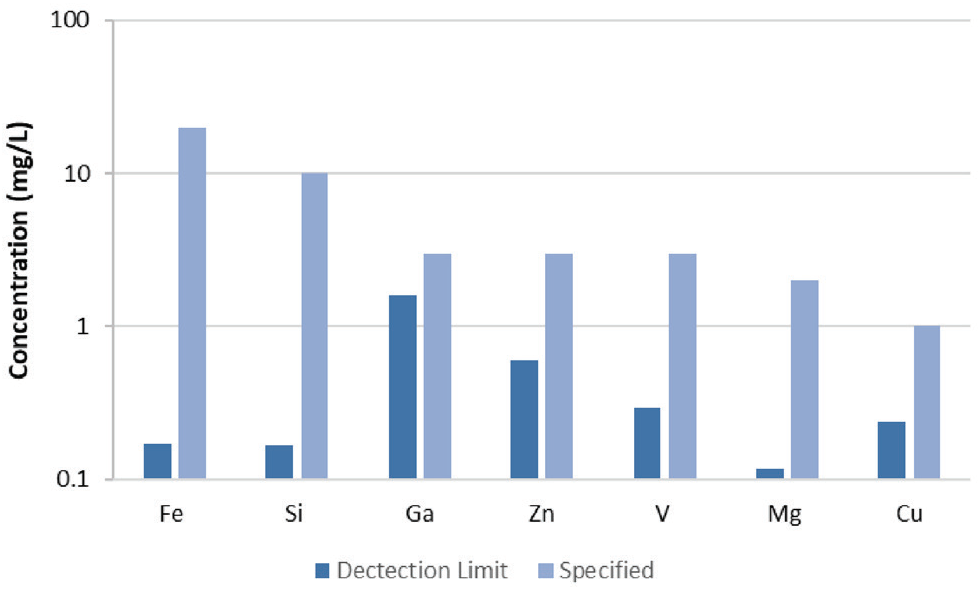

Finally, detection limits were established by performing seven consecutive measurements of a 1% Al solution, then multiplying the standard deviation by 3.14. The detection limits are below the specified levels (Figure 3), providing confidence that the specified concentrations can be easily measured.

Figure 3. Detection limits in 1% Al (corrected for 100x dilution) compared to specification limits. Image Credit: PerkinElmer

Conclusion

This work demonstrates the capability of the Avio 220 Max hybrid simultaneous ICP-OES, with simultaneous background measurements, to accurately determine impurities in aluminum, as specified in the London Metal Exchange. The required detection limits were met by using short read times, and a total analysis time of only one minute per sample.

This methodology has proved to be stable over four hours (the maximum time evaluated), a result of the considerate instrument design which prevents build-up of samples on the interface.

Consumables Used

Table 4. Source: PerkinElmer

| Component |

Part Number |

Sample Uptake Tubing: Black/Black

(0.76 mm id) PVC, Flared |

N0777043 |

Drain Tubing: Gray/Gray

(1.30 mm id), Santoprene |

N0777444 |

Aluminum Standard,

10,000 μg/mL |

N9304111 (125 mL)

N9304110 (500 mL) |

Gallium Standard,

10,000 μg/mL |

N9303772 (125 mL) N9300119 (500 mL) |

Iron Standard,

1000 μg/mL |

N9303771 (125 mL) N9300126 (500 mL) |

Magnesium Standard,

1000 μg/mL |

N9300179 (125 mL) N9300131 (500 mL) |

Scandium Standard,

1000 μg/mL |

N9303798 (125 mL) N9300148 (500 mL) |

Silicon Standard,

1000 μg/mL |

N9303799 (125 mL) N9300150 (500 mL) |

Zinc Standard,

1000 μg/mL |

N9300178 (125 mL) N9300168 (500 mL) |

Autosampler Tubes,

case of 500 |

B0193233 (15 mL) B0193234 (50 mL) |

Acknowledgements

Produced from materials originally authored by Ken Neubauer, from PerkinElmer., Inc. (Shelton, CT).

References

- “Special Contract Rules for High Grade Primary Aluminum”, The London Metal Exchange.

- “The Avio 220 Max ICP-OES: A Unique Double-Monochromator Optical System”, Technical Note, PerkinElmer, 2020.

- “Avio 220 Max ICP-OES Custom-Designed Solid-State Detector with Hybrid Simultaneous Analysis”, Technical Note, PerkinElmer, 2021.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.