Calcined Petroleum Coke (CPC) is a graphite-based material commonly used in metallurgy, fuel production, and aluminum production. As a derivative of raw petroleum coke, it occurs through a high-temperature process.

CPC has excellent electrical conductivity and contains high amounts of carbon. The CPC’s potential quality as an electrode is dependent on the crystallite size (CS, Lc). Because of this, it is critical to evaluate the CPC crystallite size. X-Ray diffraction (XRD) is an excellent method for CS determination that is in accordance with the ASTM D5187 standard.

Lc is calculated using the formula:

Δpo = 2(sinθ2 – sinθ1)/λ

This formula comes from the fundamental relationship between the size and the peak width of scattering domains. This was established in the Scherrer equation.1

where: θ1 = lower angle at half peak intensity width

θ2 = higher angle at half peak intensity width

λ = incident wavelength

Lc = (Kλ)/((βobs – βinst)cosθ)

K = arbitrary constant 0.89–1.39

λ. = incident wavelength

βobs = measured peak line breadth

βinst = instrument peak line breadth contribution

θ = angular location of the diffraction peak in degrees

Later formulas can derive an expression for Lc that is accurate for calcined petroleum coke.

Lc = 0.89/Δpo

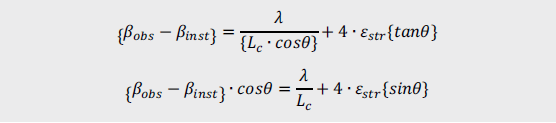

The Williamson-Hall plot starts from the deconvoluting contributions of strain and size on the peak widening, resulting in more precise Lc values. 2

εstr = strain component

Instrument and Software

Figure 1 shows the Thermo Scientific™ ARL™ X’TRA Companion X-Ray Diffractometer. It is a simple, user-friendly benchtop XRD system for process control and more advanced applications.

The ARL X’TRA Companion uses a 160 mm radius θ/θ goniometer in Bragg-Brentano geometry paired with a 600 W X-Ray source (Cu or Co).

Soller slits and divergence manage the axial and radial adjustment of the beam, while a variable beam knife reduces air scattering.

Additional options include an integrated water chiller. With a state-of-the-art solid-state pixel detector (55 x 55 μm pitch), the ARL X’TRA Companion offers exceptionally speedy data collection and arrives with one-click Rietveld quantification capabilities and automated result transmission to a Laboratory Information Management System (LIMS).

Figure 1. ARL X’TRA Companion diffraction system. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Experimental

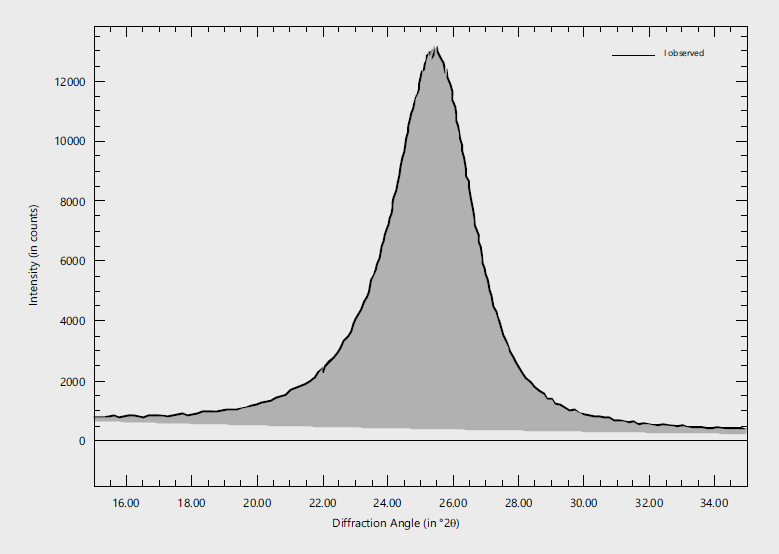

Using Cu Kα (1.541874 Å) radiation, graphite certified reference material RDC-1104 from R&D carbon was measured in reflection for two minutes. To minimize penetration depth error, the sample was prepared in a zero-background sample holder, and sample spinning was used during acquisition.

Figure 2. Measurement of RDC-1104 Graphite sample. Data were obtained at room temperature. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Results

Making use of the Scherrer formula with the FWHM of the [002] reflection of graphite leads to a Lc of 28.0 Å (see Figure 2). This is in ideal comparison to the certified value of 28.5(15) Å.

The FWHM was ascertained through profile fitting the graphite [002] reflection with a Pseudo-Voigt function. This method is compliant with ASTM D5187 because it is a computational approach to determine Lc. The Williamson-Hall method did not influence the analysis results as this graphite sample exhibits no strain.

Conclusion

The ARL X’TRA Companion is well suited to ascertain the crystallite size in CPC samples according to ASTM D5187.

References and Further Reading

- P. Scherrer, Göttinger Nachrichten Gesell. 1918 2, 98-100.

- G. K. Williamson, W. H. Hall, Acta Metall. 1953, 1, 22-31.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Solutions for Industrial and Safety Applications.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.