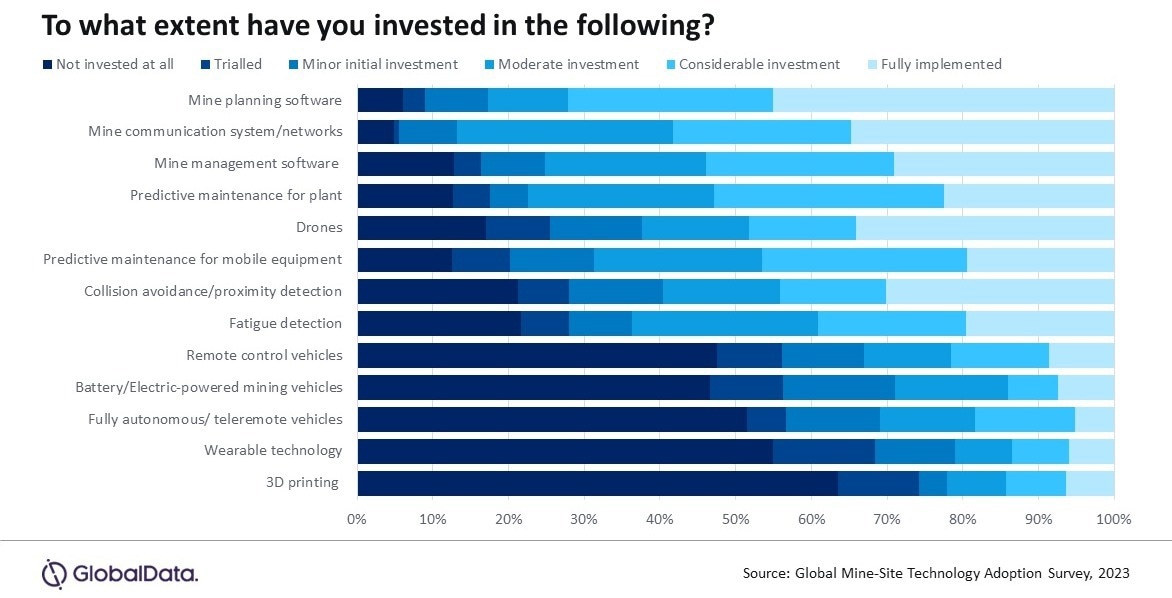

High levels of investment are being made in areas such as mine planning and management software, mine communication, and predictive maintenance, with increasing levels of investment in safety-related technologies that include drones, collision avoidance, and fatigue detection, according to the latest global mine-site technology adoption survey by GlobalData, a leading data and analytics company.

Drones were found to be principally employed for surveying and mapping (90% of those using drones) and monitoring and inspection (71%), with 33% using for tailings dam monitoring and 31% specifically for safety purposes. In Australia and Africa, the percentage of mines using them for safety purposes is 56% and 36%, respectively. Image Credit: GlobalData

Drones were found to be principally employed for surveying and mapping (90% of those using drones) and monitoring and inspection (71%), with 33% using for tailings dam monitoring and 31% specifically for safety purposes. In Australia and Africa, the percentage of mines using them for safety purposes is 56% and 36%, respectively. Image Credit: GlobalData

The annual survey asked 150 senior mine-site personnel regarding the degree to which they had invested in a range of technologies, and expectations for future investment. Over the last five years, the share that had invested in drones has risen from 44% to 74%, collision avoidance from 62% to 72%, and fatigue detection from 53% to 72%. Fatigue detection also had the third-highest share of respondents who expected to invest in the technology in the next two years (38%), after predictive maintenance for equipment (40%) and mine management software (39%).

David Kurtz, Research & Analysis Director at GlobalData, comments: “While the use of mine planning and management software, and communications systems has been high across the globe for many years, recently miners have invested more extensively in areas such as drones, collision avoidance, and fatigue detection, helping to ensure a safer working environment.’’

Some 30% of respondents indicated that they had fully implemented collision avoidance technology, with the largest share having invested in Australasia, and the highest share expecting to invest in the next two years in the Americas at 37%. Respondents were also asked about the alignment of the majority of their fleet with the Earth Moving Equipment Safety Round Table (EMESRT) framework, and specifically the top three levels of incident control, which deal with notice to the operators (Level 7), alert controls (Level 8) and intervention controls (Level 9).

Of the respondents, 21% were at Level 7, 31% at Level 8, and 18% at Level 9. However, over the next two years, the share with the majority of their fleet at Level 9 is expected to rise from 18% to 28% to provide a faster response to any possible collision.

Kurtz concludes: “Across the regions, Australasia was marginally ahead of the other regions in terms of the degree to which mines had invested in drones, collision avoidance, and fatigue detection, while the majors ranked above the mid-tier miners on collision avoidance and fatigue detection in particular, and surface mines had invested to a much greater extent than underground when it came to drones.”