Image Credit: Gianmix/Shutterstock.com

X-ray diffraction (XRD) has become a widely used technique on materials which are crystalline in nature. In many cases, the samples analyzed using XRD are inorganic, but there are some exceptions where organic molecules adopt a more crystalline structure. In this article, we look at how XRD can be used to identify materials recovered from mines.

What is XRD?

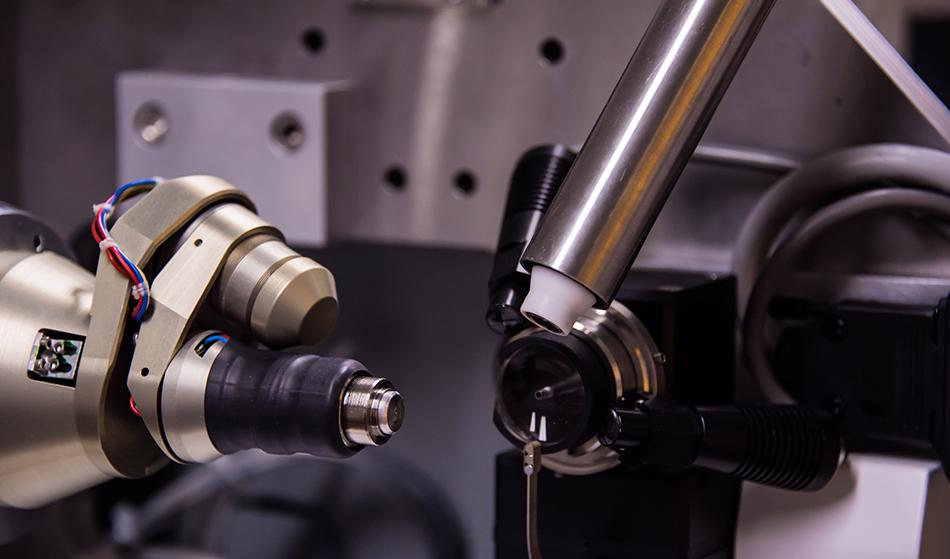

XRD is an analytical technique which deduces the molecular and atomic structure, as well as the atomic spacing, of a material through the refraction of monochromatic X-rays off its crystal lattice. Each element refracts the X-rays differently, thus a picture is built up of the material’s atomic structure, enabling its identification. In most cases, the structure is compared to a database of known structures, giving the operator a clearer and more accurate result of the sample under analysis.

XRD capitalizes on the constructive interference of monochromatic X-rays as they pass through the crystalline lattice of the analyzed material. XRD generates X-rays using a cathode tube and a monochromator to produce monochromatic X-rays (X-rays with only a single wavelength frequency). The light is then concentrated and directed towards the sample.

As the X-rays pass through the sample a constructive interference will occur is the conditions satisfy Braggs Law. Braggs Law describes the scattering of electromagnetic radiation off atoms and is dependent on both the diffraction angle and the lattice spacing of the crystal lattice. It is often given in equation form: nλ=2d sin θ. When the X-rays interact with the atoms in the crystalline lattice, the sample is scanned through an angle of 2θ (where θ is the scattering angle), enabling the diffraction pattern to be observed in all directions. This is due to the random orientation of the material when it exposed to electromagnetic waves, and the elastic scattering of X-rays (scattered X-rays have the same energy and wavelength as the incident X-rays).

Applying XRD to Materials Found in Mines

XRD is an ideal technique for studying the minerals found and recovered from mines due to their crystalline structure. It is a technique mainly used during mineral processing when the minerals are located, identified and processed from their ores into valuable materials that can be sold or used in products or other materials.

XRD is now a technique that can be used in the field as well as the laboratory and as a result, its use is more widespread in the mineral processing industry. In these scenarios, XRD can be used to deduce the structure of minerals present in an ore or already in the processing stream. It is a technique that can also deduce the quantity of each mineral present in a sample. XRD has become a useful technique for those in the mining industry as it can be used to inform the geologists and process engineers of the best optimization protocols for processing ores, especially when they contain a wide range of minerals.

XRD also helps identify gangue minerals, those minerals, compounds or molecular systems present in an ore which may cause complications during the processing stage. In some cases, the processing might involve floating the ore, but others may require the use of acid. In the former case, some gangue minerals can float alongside the desired minerals, resulting in impurities in the processed minerals. In the latter case, some gangue mineral can absorb the acid used to isolate the intended mineral. In these cases, the volume of acid required to isolate the desired minerals can significantly increase, increasing the safety risks of the process (and the subsequent waste) as well as the cost.

The use of XRD in these cases can pre-emptively determine the presence of gangue minerals in the ore and proactive steps can be taken to remove them before the processing stage. This ultimately leads to purer mineral products, reduced costs, and a more streamlined and efficient processing stage.

Sources and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.