Mining and other industries pollute the environment with the production of various by-products such as highly acidic wastewater. Acid mine drainage (AMD) wastewater has become a serious global threat to the environment and living organisms, causing several detrimental effects. Scientists have developed various biological and chemical-based strategies to combat this problem. Virtual Curtain Limited (VCL), an Australian company, has offered several cost-effective remedies to reduce the damages caused by AMD wastewater.

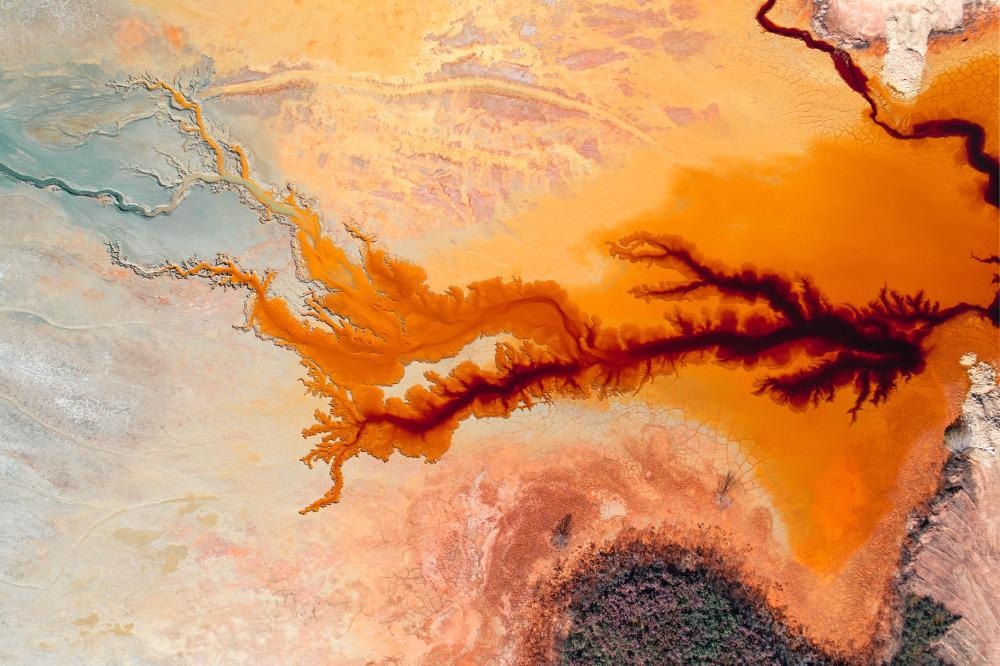

Image Credit: Sky Cinema/Shutterstock.com

A Brief Overview of Acid Mine Drainage

AMD is initiated by the hydro-geochemical weathering of rocks containing sulfide (marcasite, arsenopyrite, pyrite, etc). These rocks typically remain in contact with oxygen and water, and the reaction is orchestrated by sulfur-oxidizing microorganisms, in the presence of iron. AMD is mostly produced as a by-product of various industrial processes associated with mining and other related industries.

These sulfate-polluted wastewaters are extremely acidic (pH 4) and contain high concentrations of metals, such as aluminum, iron, manganese, zinc, copper, mercury, lead, and other heavy metals. It also contains metalloids such as arsenic and sulfur. The drainage composition varies significantly from one region to another because of local geology, group of microorganisms, microclimate, and source water.

AMD is abundantly found in operating, abandoned, and open-pit sites. This wastewater freely mixes with underground and surface water, rivers, and other water bodies that are in proximity. Owing to its composition and acidic pH, AMD contamination has many lethal effects, including loss of biodiversity, deterioration of aquatic ecosystems, and massive infrastructure corrosion.

Strategies to Remediate and Neutralize AMD Wastewaters

Many treatments have been developed for remediating AMD contamination. A common method used for the treatment of acidic effluents is the addition of alkali (e.g., sodium hydroxide) to AMD wastewaters, which rapidly changes the pH level. Besides neutralization work reagents (alkali), other chemicals such as hydrogen peroxide and carbonates are also added to promote precipitation of common metallic contaminants present in AMD wastewater.

Many biological treatments (bioremediation) of AMD have been developed. These are preferred over chemical-based conventional treatments because bioremediation of AMD wastewater is associated with low operational and labor costs, generation of less hazardous water, easy process design and control, and high recovery of sulfate and valuable metals. The biological process of remediation of AMD wastewater involves the application of sulfate-reducing bacteria that can recover metals and sulfates in the form of metal sulfides. Besides the recovery of metals, SRB metabolism is also associated with acidity neutralization of AMD wastewaters because of the resulting alkalinity from its biochemical reactions. Some of the examples of sulfate-reducing bacteria are Desulfotomaculum sp, Desulfosporosinus sp, Thermodesulfobacterium sp, and Thermodesulfovibrio sp.

Remediation and Neutralization Solution Provided by VCL

VCL provides long-term remedies to the problems associated with sub-surface and above-ground geochemically complex AMD wastewater. The solutions provided by VLC are based on the synthesis and application of hydrotalcite, which is a layered double hydroxide mineral, resembling talc, and composed of aluminum and magnesium.

VLC has been involved with supporting the development of the Commonwealth Scientific and Industrial Research Organization (CSIRO)’s patented hydrotalcite-based technology (HT) and has obtained the right to use and commercialize this technology under license. CSIRO is an Australian Government agency responsible for scientific research.

Hydrotalcites are naturally formed or can be produced synthetically, and are characterized by positively charged mixed metal hydroxide layers separated by interlayers that contain water molecules and a variety of exchangeable anions. VCL uses the formation of hydrotalcite using commonly present elements such as iron, magnesium, and aluminum in AMD wastewater. It can also use alternative components reagents that are commercially available to produce hydrotalcite-minerals by capturing the metallic contaminants. The newly formed mineral-hydrotalcite can be easily removed from wastewater streams.

The technology is applicable for both new mining or industrial projects, or existing projects that produce harmful, acidic, and contaminated wastewater. It can also be used in uranium leach mines sites. Typically, the HT-based method is a one-step process. This method is capable of remediating large pit lakes formed from open-cut mines filled with AMD wastewaters. Treatment of sub-surface contaminated aquifers involves the administration of a “virtual curtain” of reagents, which leads to neutralization of groundwater plume. Many industrial plant wastewaters are processed using in-circuit treatments.

Advantages of Application of Hydrotalcite-Based Technology

Some of the advantages of HT over conventional remedial methods of acidic and contaminated wastewater are discussed below:

- It is a one-step process that is capable of removing both anions and cations simultaneously, with minimal sludge production. According to VCL, the production of sludge is 90% less than the lime-based conventional method.

- This technology involves rapid de-watering and additives are dissolved quickly for solution-solution mixing reactions.

- Rapid settling and de-watering lead to the availability of a large proportion of the treated water for reuse or discharge.

- The formation of hydrotalcite is versatile, i.e., it can be easily and rapidly formed using different types of water (acid, neutral, alkaline, and (hyper)saline) and commercially available reagents.

- The metallic precipitates, obtained via the HT method, contain high concentrations of uranium, copper, rare earth elements, and other valuable metals.

- Hydrotalcites can be stabilized via chemical processes that help in the permanent storage of a range of radionuclides produced during or after the cessation of uranium mining.

References and Further Reading

Virtual Curtain Limited.

Rambabu, K. et al. (2020) Biological remediation of acid mine drainage: Review of past trends and current outlook. Environmental Science and Ecotechnology. 2.100024. https://doi.org/10.1016/j.ese.2020.100024

RoyChowdhury, A. et al (2015) Remediation of Acid Mine Drainage-Impacted Water. Current Pollution Reports. 1. pp. 131–141. https://doi.org/10.1007/s40726-015-0011-3

Tosun, I.Y. (2017) Thickener Water Neutralization by Mid‐Bottom and Fly Ash of Thermal Power Plants and CO2: Organic Humate Mud of AMD Treatment for Remediation of Agricultural Fields. IntechOpen, https://www.intechopen.com/chapters/56608

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.