Mar 18 2021

The team at ANSTO, Australia’s knowledge centre for nuclear science and engineering have developed a new, cutting edge technology that may provide new insights into climate change and minimise the effects of mining by making it more efficient.

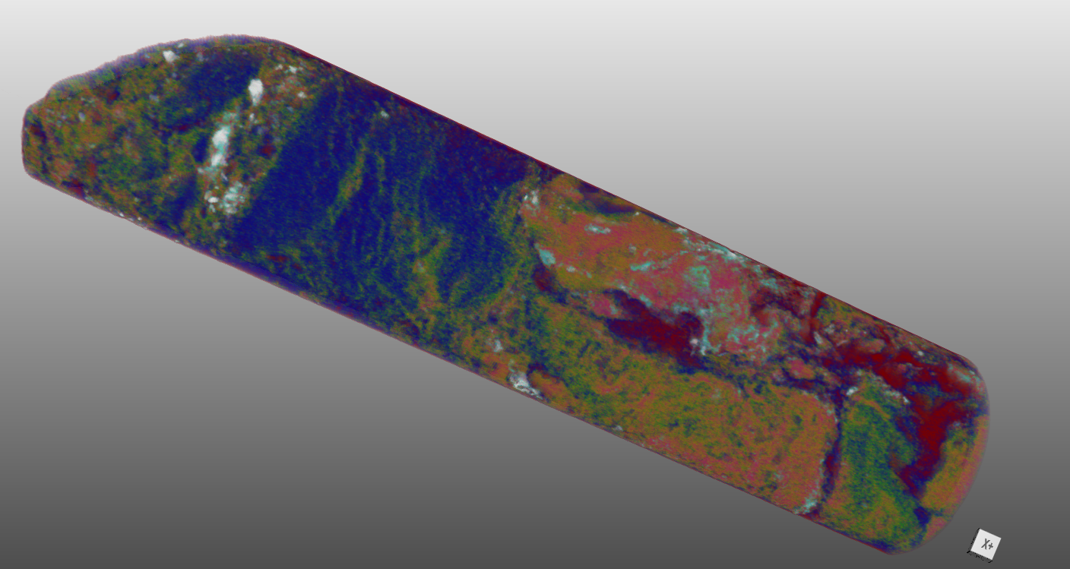

Image Credit: ANSTO

Using ‘Dingo’, one of the highest intensity neutron imaging machines in the world, ANSTO scientists have figured out how to greatly reduce the time needed to measure the exact mineral content of core samples.

Senior Instrument Scientist at ANSTO’s Australian Centre for Neutron Scattering Dr Joseph Bevitt developed the new technology which has the potential to significantly change the way minerals are explored around the world.

“At the moment, many drill core samples are X-rayed for surface mineral content, which is essentially a guesstimate,” Dr Bevitt said.

“While some drill cores are fully 3D imaged with X-rays, many cannot be studied in this way because X-rays do not have sufficient penetrating power.”

“Our neutron-imaging technology creates a full 3D map of the core, delivering the total mineral content for metal-rich and dense ores.”

The procedure is non-destructive and as quick as traditional X-rays and would mean the search for valuable minerals and their processing can be carried out in a more targeted manner, resulting in reduced environmental effects of mining.

“If you take gold for example, current X-ray technology is limited as to what it can reveal, especially when more abundant heavy metals such as lead are present in the ore as these prevent 3D X-ray imaging,” Dr Bevitt explains.

“Our 3D neutron tomography measures the exact gold content of a mining core, with neutrons able to image through lead, iron and other abundant metals, allowing parties to know the exact size of the lode underground through core samples without breaking earth.”

An upcoming upgrade to ANSTO’s 3D neutron imaging facility will also ensure simultaneous 3D neutron and X-ray imaging is achievable, enabling even more accurate mineral identification and quantification.

“This technology is revolutionary and a first for Australia,” Dr Bevitt said.

3D neutron tomography also has enormous benefits across numerous academic fields including environmental science, palaeontology, engineering, and cultural heritage. Speeding the method up opens the possibility for more, and deeper, research opportunities.

“By examining fossils, for example, we can learn how animals and plants evolved to thrive through changing environmental conditions. This research is essential as we seek solutions to the problems caused by climate change,” Dr Bevitt said.

“The device also can look for material imperfections down to a tenth of a human hair without damaging a sample. This is an integral part of ensuring the safety of materials being used for space and ocean exploration.”

Applications are currently open for academic researchers or commercial clients nationwide who may require access to ANSTO’s neutron imaging device or,any of its 13 other neutron scattering instruments for their research.

“This is one of the world’s most advanced neutron imaging machines, at one of the world’s top scientific facilities. For many researchers this will be a once-in-a-lifetime opportunity to validate their theories.”

The rig was developed in collaboration with Dr Tim Murphy from Macquarie University. For more information about how to apply to collaborate on the Dingo, visit the ANSTO website.

This is the latest cutting-edge mining technology developed by ANSTO. Late last year, Dr Jessica Hamilton received an award from the Australian Academy of Science, following the development of her technique for using mining waste for carbon dioxide capture.

Dr Hamilton’s novel process sees mineral waste reused with acid neutralised and the CO2 captured. Valuable products are produced in the form of carbonate minerals and the transformation of stockpiles of mineral waste into enriched ore that can be re-mined.

Following the development of her technique, Dr Hamilton’s process is now being tested in diamond mines in Africa and Canada.”