ZEN core from Zeiss has the ability to tackle more than just microscopy imaging. The ZEN core is considered to be the most extensive suite of imaging, analysis, segmentation and data connectivity tools that have been utilized for multi-modal microscopy in linked material laboratories.

Enjoy its Highlights

- Simple to configure — Users can benefit from an adaptive user interface.

- An infrastructure solution is available for the connected laboratory. Users can keep their data together in laboratories instruments and locations.

- Advanced imaging and automated analysis. Utilize built-in acquisition routines and profit from the consistency of repeatable workflows.

Image Credit: Carl Zeiss Microscopy GmbH

Highlights

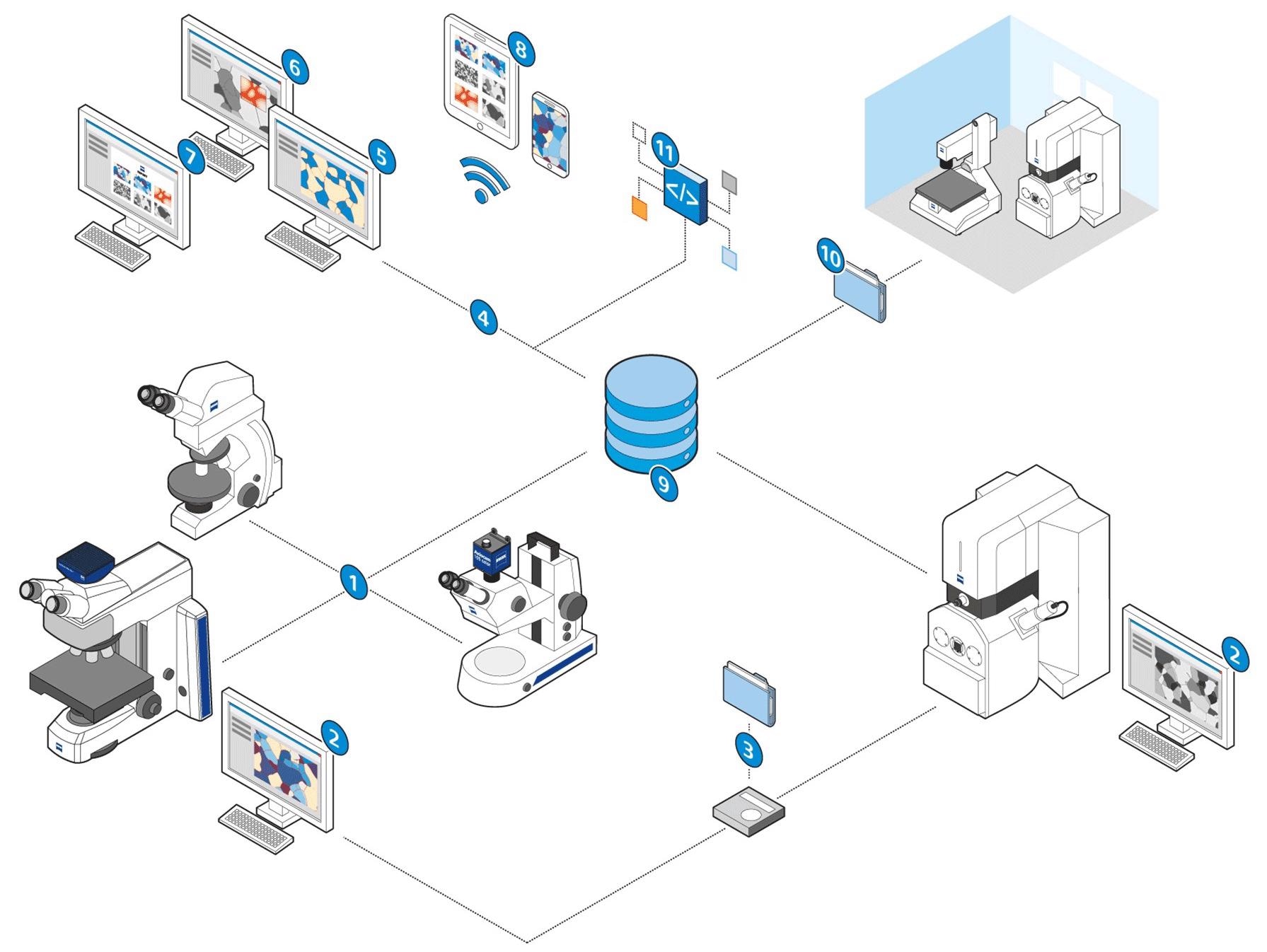

One Interface for all ZEISS Microscopes in a Multi-user Environment

Image Credit: Carl Zeiss Microscopy GmbH

Right from the entry-level stereo microscopes to completely automated imaging systems, ZEN core offers a joint user interface for ZEISS microscopes and cameras. ZEN core allows the link of light and electron microscopy in multi-modal workflows and offers connectivity between laboratories, systems and locations.

- Automated segmentation

- Combined reporting

- Microscope and camera control

- Data acquisition and analysis are available

- Comes with correlative microscopy

- Mobile access available

- Central data management

- Post-acquisition analysis can be performed

- Interfaces available for further analysis

- Contextual analysis

- Connectivity is possible between systems, laboratories and locations

User Management Designed to Assure Data Repeatability and Integrity

- Make multiple user accounts with specified privileges and roles as per the requirements of users.

- Administrate all users in an effective manner with the help of ZEN Data storage as a central hub for all users’ connected microscopes.

- Create and control users directly in ZEN core—or link to ActiveDirectory and reuse those user accounts.

- Access can be protected with passwords and leverage broad abilities to put password rules and expiration times in place.

Image Credit: Carl Zeiss Microscopy GmbH

Perform Automated Segmentation, Contextual Analysis and Reporting

ZEN analyzer is a desktop version of ZEN core that has been developed for activities that can be performed separately from the microscope. The instrument has not been blocked for post-processing tasks. Rather, it can be used to run other experiments anytime, anywhere and with genuine efficiency.

- Providing remote access to ZEN Data storage.

- The perfect solution for segmentation and analysis, as well as for reporting and making job templates.

- Allows users to utilize all workbenches that come with ZEN core, thereby offering complete control of all data and templates. All these can be accessed from the users’ desks.

Image Credit: Carl Zeiss Microscopy GmbH

Materials Modules for Metallography Applications

The ZEN core consists of material modules for the determination of grain sizes, phases and layer thicknesses as well as categorizing graphite particles and non-metallic inclusion analysis, and offers all significant metallographic applications under an even user interface.

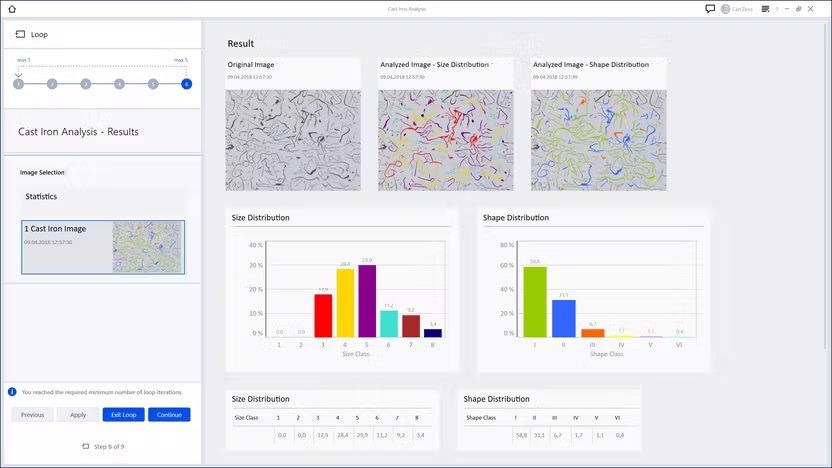

Cast Iron Analysis

Based on the material’s chemical composition and process parameters, graphite particles in cast iron can take place in various shapes and distributions. This impacts the material’s mechanical properties.

Users can examine the shape and size of graphite particles in a completely automatic manner. Achieve the spheroid number as per the EN ISO 945-1: 2008 + Cor.1:2010. Identify the nodularity of vermicular graphite and analyze the content of graphite particles in area percentage.

Cast Iron Analysis: Size and shape distribution. Image Credit: Carl Zeiss Microscopy GmbH

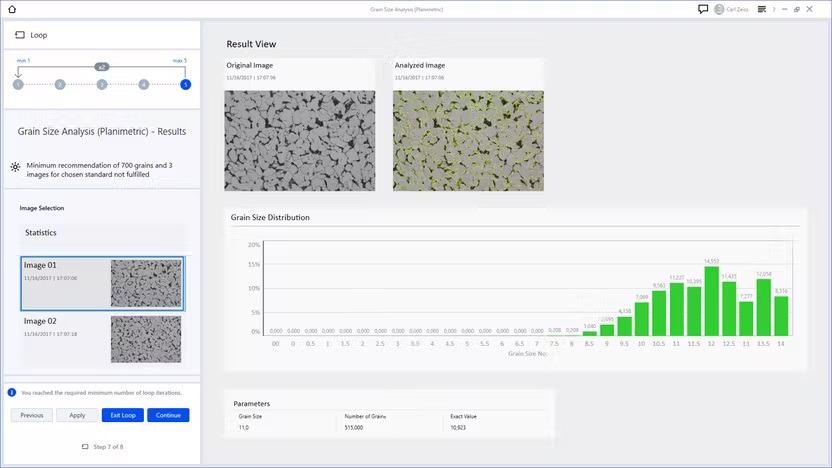

Grain Size Analysis

The grains’ size and distribution are linked directly to the properties of the material. Users can measure the crystallographic structure of their materialographic samples as per international standards. Three assessment methods enable users to characterize their material:

- Planimetric technique available for automatic grain boundary reconstruction

- Comparison technique for manual image evaluation along with relative diagrams

- Intercept technique with a range of various chord patterns to interactively identify and count the intersections along with grain boundaries

Grain Size Analysis: intercept method. Image Credit: Carl Zeiss Microscopy GmbH

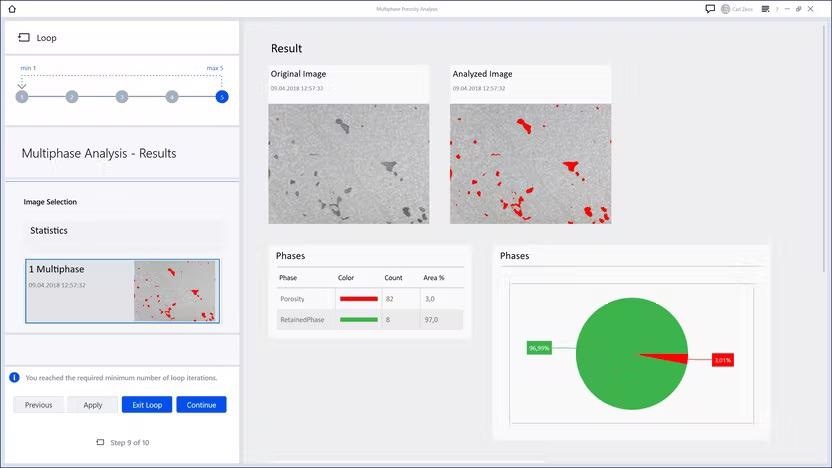

Multiphase Analysis

Any part of the material having a diverse crystal structure could be considered as a “phase.” Various phases are isolated from one another by different boundaries. Distribution and orientation of phases tend to impact the material properties like hardness, elongation or strength at break.

Users can examine the phase distribution in their samples. The size, shape or orientation can be identified in an accurate and completely automatic manner. Users can make use of this distribution analysis to gain information regarding the porosity of additive manufactured material.

Multiphase Analysis: result view with distribution of different phases. Image Credit: Carl Zeiss Microscopy GmbH

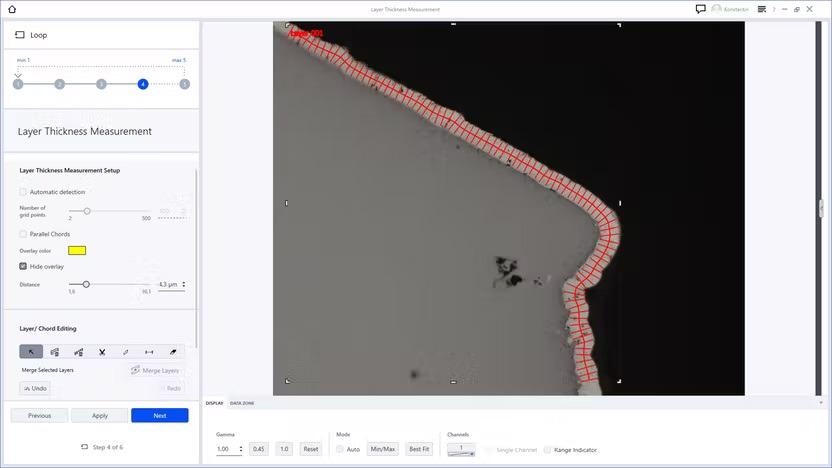

Layer Thickness Measurement

Quantify the thickness of coatings and platings or the depth of hardened surfaces in the sample’s cross-section.

Complicated layers systems can be assessed in either an interactive or automatic manner. The module evaluates the course of the measurement chords based on the gradient present.

Users can obtain the results from their part in a clear report consisting of images, sample data and measurement values, like the utmost and least chord lengths, mean and standard deviation.

Layer Thickness: automatic detection of a layer. Image Credit: Carl Zeiss Microscopy GmbH

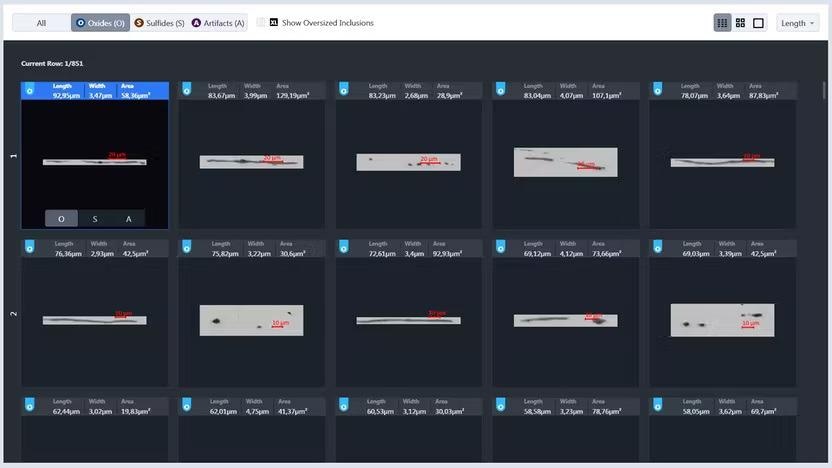

Non-Metallic Inclusion Analysis (NMI)

Metallographic analysis of NMI has been governed by industry standards that are aided by ZEN core guiding the user easily and rapidly via the workflow. This produces a report and inclusion gallery flexible with the standards.

The features like strong inspection views and automated deformation axis make analysis simple, repeatable and intuitive. ZEN core users are able to provide their customers with complete traceability and data integrity in NMI analyses with the availability of extra GxP functionality, thereby implying that the grade certification is auditable, which is especially beneficial for customers in controlled industries.

NMI: Global Results view provides the option to toggle between inclusion types: oxides, sulfides, and artifacts. Image Credit: Carl Zeiss Microscopy GmbH

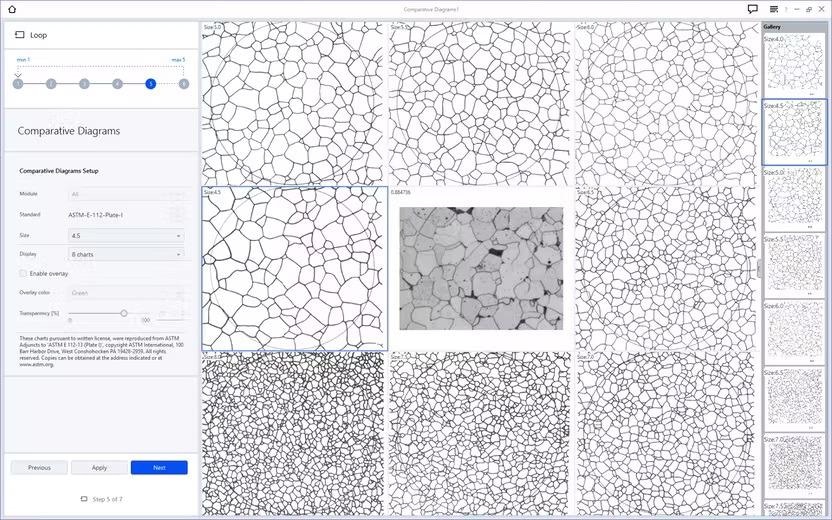

Comparative Diagrams

Users can make their wall Charts digital. Compare users’ samples under the microscope with relative diagrams directly on their screen.

Users can select between various schematic micrographs with particular characteristics. These alter slowly from image to image and might pertain to carbide precipitation in steel, grain size or quality of sample preparation.

Furthermore, the module offers a chart series creator to develop users’ comparison diagrams, for example, for a pass or fail criteria in quality control or best target preparation images available for individual material microstructures of users.

Comparative Diagrams: Compare the sample with standardized or customized wall charts. Image Credit: Carl Zeiss Microscopy GmbH

Advanced Imaging and Analysis

-

Automation for Light Microscopes: ZEN core offers an extensive range of choices for automated image acquisition:

-

Enhanced Depth of Field: Users can automatically obtain images with improved depth of field

-

Online Panorama: Users can obtain panorama images on coded and non-coded stages

-

Free-Form Tiles: Users can easily specify stitching areas to make highly resolved images

-

Linkam Stage Control: Users can note materials under temperature.

-

Multi Channel Acquisition: Obtain images with several channels in one go in an automatic manner, for example, multiple fluorescent channels or just bright- and darkfield.

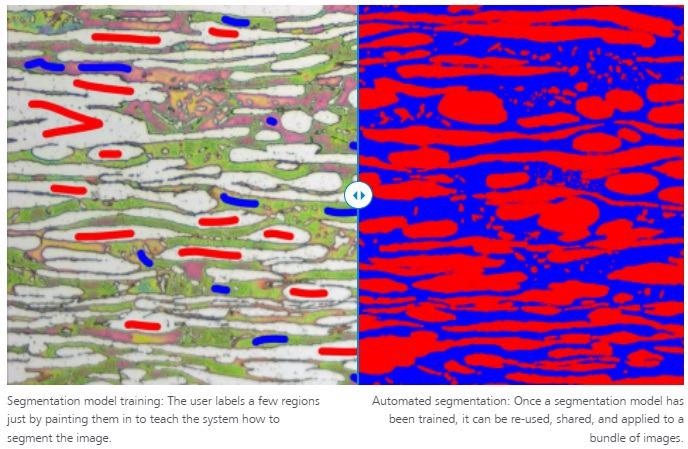

ZEN Intellesis Enables Image Segmentation by Machine Learning

Segmentation is considered one of the biggest hardships that have been experienced by microscopists at present. However, users could avoid errors and user bias by utilizing machine learning for image segmentation.

ZEN Intellesis Segmentation

This software module offers strong machine learning segmentation of multidimensional images such as 3D datasets. It has been developed for the smooth integration of multiple imaging modalities and for obtaining excellent segmentation on any single image.

- Users can use their expertise to train the software and allow it to do the tiresome segmentation. They can also import steadfast networks trained elsewhere (for instance, on www.APEER.com)

- Users can examine images automatically that once had to be manually processed. Users can train a model to segment them.

- Users can profit from saving time in sample preparation as ZEN Intellesis Segmentation could be adapted to their preparation process. Reproducibility is ensured as the stored analysis program could be utilized again, sample by sample, or held to tackle new samples

Image Credit: Carl Zeiss Microscopy GmbH

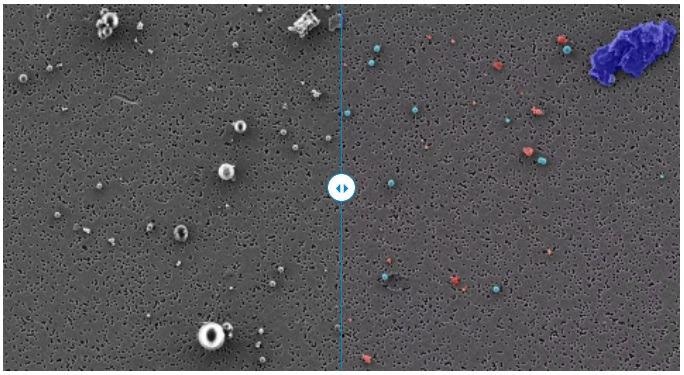

ZEN Intellesis Object Classification

At times segmenting objects like particles, grains or inclusions is direct, but it could still be difficult to sort them into different classifications. Also, machine learning-based segmentation methods might find it hard in this case since they only consider the look of pixels and are unable to take derived properties of pixel clusters (objects) into account as well.

Currently, ZEN Intellesis Object Classification provides a simple method to categorize already segmented objects into subclasses. An object classification model could be trained to execute the classification in an automatic manner.

- Rather than looking at separate pixels, the model utilizes over 50 properties quantified per object to differentiate them. Such derived measurements consist of geometric and intensity-based features.

- As ZEN Intellesis Object Classification functions on tabulated rather than image data, the classification process is much quicker compared to segmentation by specailly trained deep neural networks.

- The classification process is separate from the prior segmentation if it was performed by classic thresholding or with the help of machine learning.

Object classification performed on standard nano- and microplastic particles (polystyrene (PS, light blue), polyethylene (PE, green), polyamide–nylon 6 (PA, dark blue), and polyvinyl chloride (PVC, red)) on a polycarbonate filter imaged with ZEISS Sigma. This correlative study combines the high resolution of an electron microscope with the analytical capabilities of a Raman microscope. The classification model is capable of distinguishing the different particle types based on their properties. Image Credit: Carl Zeiss Microscopy GmbH

Infrastructure Solutions for the Connected Laboratory

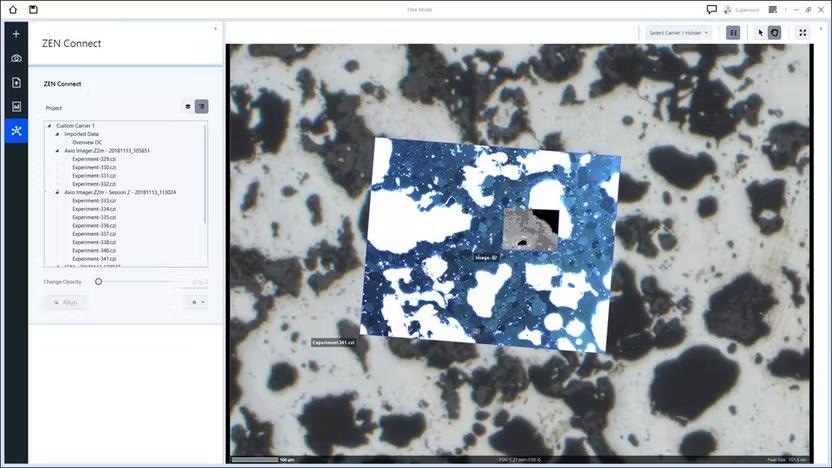

ZEN Connect: Quality Data Put in Context

Users can arrange and envision various microscopy images and data from the same sample in their context, all in the same place. For sample-centric analysis, ZEN Connect workflows allow users to get from a rapid overview image to improved imaging with several modalities. The correlations between the images at different scales can be viewed and navigated easily.

The interdependencies of the various datasets could be stored, exported and re-used in a Client-Server Database–ZEN Data Storage. It allows exportable angle, line and area measurements to be performed in the workspace within or across aligned images. Also, ZEN Connect allows combined reporting throughout the connected images and datasets.

ZEN Connect user interface: images at different scales can be easily navigated. Image Credit: Carl Zeiss Microscopy GmbH

Correlative Microscopy

Correlative microscopy is a strong method for integrating the complementary attributes of various microscopic methods to achieve the utmost meaningful data from parts or materials samples.

The ZEN core is the ZEISS correlative microscopy interface that has been specifically developed for use in materials analysis available on all ZEISS light- and electron microscopes with motorized stages.

- Samples can be transferred between LM and EM systems quicker compared to earlier

- Relocate regions of interest in an automatic manner.

- Users can gather the appropriate information

- Efficiency and throughput can be improved

- Well informed material decisions can be taken

ZEN Data Storage: Central Data Management in the Connected Laboratory

Since digitization continues to enhance microscopic investigations, users are experiencing an ever-growing mass of images and data that needs to be controlled, all the more so in multi-user laboratories.

ZEN Data Storage allows users to isolate image and data acquisition from post-acquisition works, thereby making everyone in the laboratory work more efficiently in several methods:

- Users can share instrument presets, workflows, data and reports in comfort

- Help users’ IT department implement security and backups

- All data can be accessed from various systems and locations

- Users’ analyses are reproducible and quality assured

- Execute multi-modal workflows and reap the utmost data from their samples

- Integrate ZEN Data Explorer with ZEN Data Storage for mobile access to data. This enables users to use their smartphones or tablet to analyze their results when users are on the go.

Image Credit: Carl Zeiss Microscopy GmbH

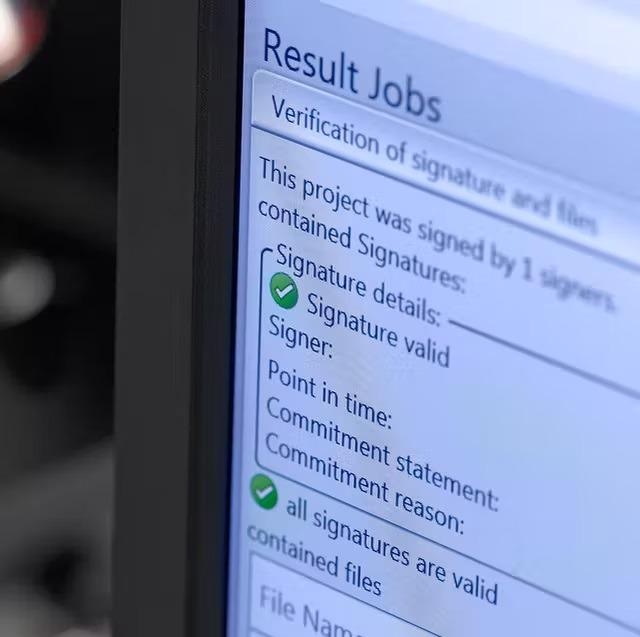

GxP Module: Secure and Compliant Microscopy Processes

The GxP module enables traceable workflows through seamlessly integrated microscopy hardware and software to meet the requirements of regulated industries. Every workflow available in ZEN core can be made GxP compliant.

- Audit trail

- User management

- Discharge procedure of workflows

- Disaster recovery can be performed

- Electronic signatures, including countersign functionality

- Checksum safety of process-critical data

GxP module: Electronic signature validation. Image Credit: Carl Zeiss Microscopy GmbH