Taiwan is committed to improving the country’s air quality, and the country has taken a series of steps towards this goal over a long period of time. An example of this commitment was the Executive Yuan’s launch of the Air Pollution Prevention Strategy in 2017, aimed at ensuring the long-term viability of a vibrant and environmentally healthy Taiwan.

This work follows the conventions outlined by governing offices, such as the Taiwan Ministry of Environment (MOENV), formerly the EPA, for the strategic planning and review of air pollution prevention and control.

Air Quality and the Challenges of Mercury Emissions

The MOENV implemented tariffs as early as 1995, aiming to control air pollution as Taiwan moved towards increasing industrialization and urbanization.

This modernization saw the island begin to experience environmental changes, with the tariffs allowing the MOENV to extend air pollution management and controls, incorporating a range of pollutants from traditional pollutants to mercury.

A number of markets worldwide face the emerging challenge of mercury, with Japan passing the Minamata Convention in Minamata City, Kumamoto Prefecture, in 2013. This is also an International Convention designed to regulate global mercury pollution.

Mercury is ubiquitous in current society, regularly used in dentures, fluorescent lamps, and industrial processes such as VCM and the production of sodium pentachlorophenate.

The MOENV has successfully implemented waste recycling to address the issue of pollution stemming from mercury, heavy metals, and mercury emissions.

The international community has primarily focused on three major industries to better manage global air pollution: coal-fired power plants, early waste incinerators, and gold mining and metallurgy.

A multi-faceted approach by the EPA on the treatment of waste and improvements to air quality from incineration plants has led to a significant reduction in mercury emissions from old or abandoned incinerators.

Taiwan noted that the United States began regulating coal-fired power plants in 1994, following this example to formulate a range of standards for coal-fired emissions.

Technologies and Controls to Improve Environment and Health

Taiwan faces several growing environmental challenges, including excessive electricity consumption, greenhouse gas emissions, pollutant releases, air pollution, and unsustainable resource consumption. The public is also becoming increasingly vocal with demands for higher levels of environmental protection.

While Taiwan is currently managing mercury emissions effectively, local government agencies continue to push the boundaries for better air quality controls.

For example, the Lulinshan Station, located at the junction of Nantou and Chiayi, is the first monitoring station in Taiwan designed for the long-term monitoring of mercury in the air, both within and around the island of Taiwan.

The MOENV maintains a long-standing agreement with the US EPA around the monitoring of mercury emissions in the air. This agreement also involves the sharing of data or relevant information to improve long-term air quality.

Taiwan is also reducing its cement production, with cement kilns now being converted to waste treatment plants. Mercury emissions from waste processing in cement kilns are now becoming a new area of concern for Taiwan’s environmentalists.

Guidelines and Tools for Addressing and Managing Air Pollution

The MOENV issued the Public and Private Places Fixed Pollution Source Fuel Co-firing Proportion and Composition Standards in March 2020. These latest guidelines feature an amendment to Article 28, Item 2 of the Air Pollution Control Law, featuring clear specifications for fuel source management.

These specifications also feature composition standards for fuel oil, raw coal, petroleum coke, and primary solid biomass fuel, and restrictions on the proportion of the mixed combustion of waste fuels.

Use of a continuous monitoring system for mercury emissions in a coal-fired thermal power plant. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Businesses can no longer purchase coal that exceeds the EPA’s set limit of 0.15 mg mercury content in coal due to this new amendment. The Taiwan Power Company had previously set its own mercury standards of 0.12 mg mercury content in coal for its operations. These new guidelines have been developed to control mercury emissions at the source level.

Mercury has a very low boiling point, meaning that widespread mercury emissions are a major issue. Mercury has become a global pollution problem because it exists in a gaseous state during the combustion process, circulating in the air, soil, and water bodies.

Mercury differs from general organic substances in that it changes from a solid phase to a gaseous phase, and from a gaseous phase back to a solid phase. Mercury attached to specific matter can be controlled physically, but mercury is challenging to control as a gas, and it will circulate worldwide in the atmosphere upon discharge.

Mercury can be managed by setting standards of mercury content in coal for coal-fired power generation, and advanced technology has the potential to further address the challenges associated with mercury in air pollution.

Jeff Socha, Senior Manager of Technology Development at Thermo Fisher Scientific, emphasizes these issues,

“Both elemental mercury and oxidized mercury can continuously be monitored by a continuous mercury monitoring system (Hg CEMS) in the flue. What is of key concern to power plant operators or environmentalists is the concentrations of both types of mercury in varying fuel and operating conditions.

“If the data shows that elemental mercury is relatively high, how does one ensure the removal of the stable elemental mercury? While we can try to convert elemental mercury into oxidized mercury through the SCR at the front end, the issue arises when the concentration of oxidized mercury is relatively high, indicating a problem with FGD.

“This raises more questions, such as whether oxidized mercury should be dissolved in water. By implementing Hg CEMS at the back end, there will be continuous data for analysis and better decision making.”

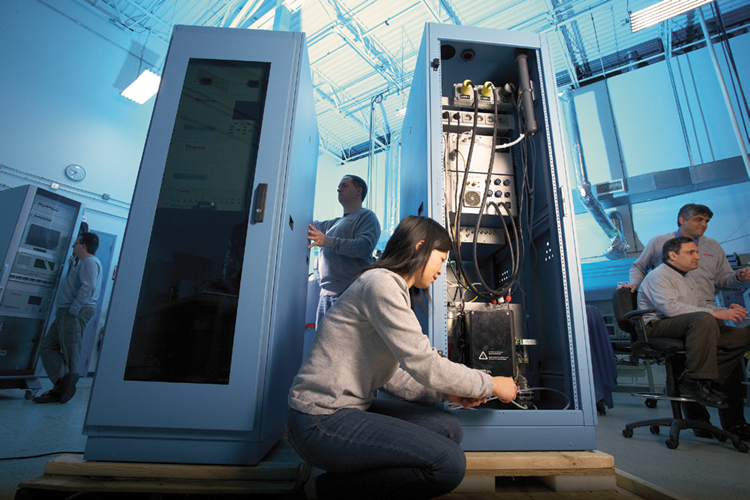

File image showing the manufacturing of a Thermo Scientific mercury CEMS system. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Ensuring clean air worldwide requires a global effort, with governments maintaining regulations designed to minimize the release of mercury, harmful toxins, and other pollutants into the air.

Thermo Fisher Scientific is working to support its customers to make the world cleaner, healthier, and safer, and ensure complete regulatory compliance via unattended and genuine continuous monitoring.

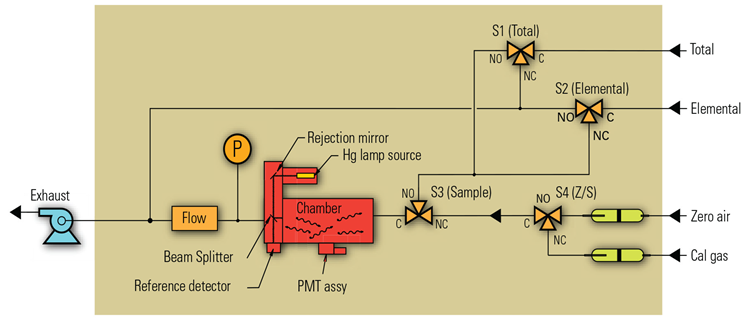

The Mercury Freedom System from Thermo Scientific is an integrated mercury emissions monitoring system specifically designed to measure elemental, ionic, and total mercury in exhaust stacks from industrial combustion sources, including waste incinerators, coal-fired boilers, and cement kilns.

The Mercury Freedom System offers regulatory compliance and peace of mind, including:

- Adherence to U.S. EPA 40 CFR Part 75 requirements with true continuous monitoring

- Able to accommodate increasingly stringent regulations thanks to the use of highly sensitive direct cold vapor atomic fluorescence technology

The system is also easy to own and operate, featuring:

- Extended umbilical line life and reduced service needs thanks to reduced umbilical temperature

- Further extension to umbilical life via a split umbilical as separate cold/hot lines

- No need to use expensive consumables

- Easy access to equipment and reduced maintenance time and cost thanks to a modular design

- A highly sensitive cold vapor atomic fluorescence analyzer requiring no expensive gold amalgamation concentrator or wet chemicals

- Rack-mountable components allow seamless integration into the majority of existing stack monitoring configurations

- Reduced space and cost requirements due to no argon carrier gas being required

Thermo Scientific™ Mercury Freedom System. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Mercury Analyzer Operation

Mercury analyzers work on the principle that mercury (Hg) atoms absorb ultraviolet (UV) light at 254 nm and become excited before decaying back to the ground energy state. This results in them emitting (fluorescing) UV light at the same wavelength: Hg +hv(254 nm) -> Hg *-> Hg + hv(254 nm).

A mercury analyzer is one of four key components of a total mercury monitoring system. The analyzer uses an advanced cold vapor atomic fluorescence technology to ensure continuous sample measurement. No additional gases or accumulations are required, and there is virtually no interference from SO2.

Probes to determine mercury emissions feature:

- A dry converter in the probe eliminates the need to transport oxidized mercury.

- Reduced umbilical temperature reduces service needs and extends the life of the umbilical line.

Thermo Fisher Scientific offers reliable probes able to:

- Accommodate high particulates

- Enable carbon carryover from plants with loss of ignition or upstream of pollution controls

Monitoring Solutions for Regulatory Compliance and Process Control Needs

Continuous emissions monitoring systems may be necessary in stationary source monitoring for a wide range of reasons.

Thermo Fisher Scientific offers a comprehensive portfolio of products and services designed to meet customers’ specific regulatory compliance and process control requirements. The company’s highly experienced experts can read air permits, integrating solutions and services in the field as required.

Every plant, facility, and customer is unique. Thermo Fisher Scientific’s team of applications specialists can offer valuable support in managing mercury emissions regulations via continuous monitoring solutions.

Acknowledgments

Produced from materials originally authored by Thermo Scientific.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.