Sponsored by Tough TechReviewed by Louis CastelMar 24 2023

As it is a simple process, installing tire pressure monitoring systems (TPMS) on a rigid dump truck (RDT) takes around 30 minutes. There are options for a connected solution, giving the fleet or site manager information on the tire performance of the whole fleet or a stand-alone installation with a screen in the cab for the driver.

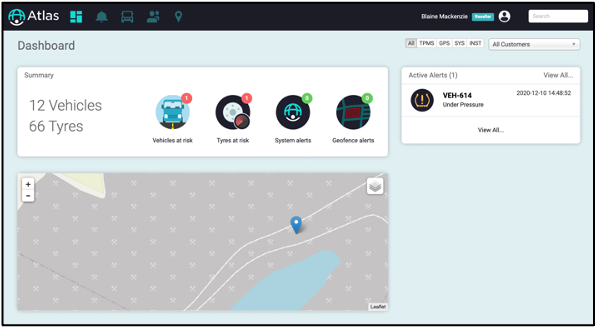

ATLAS can track machines on any mining/extraction site, off-highway location, or haul road.

Image Credit: Tough Tech

After Market – The Whole Fleet

With only a 30-minute installation process, it is possible to equip the entire fleet with an ATLAS TPMS system without the costly need to take the machine out of action for an extended period. With the benefits of TPMS, a company can save thousands of pounds.

Even the Most Challenging of Tires

Whether utilizing 3 or 5-piece rims, monitoring earthmover tires proves a challenge. ATLAS TPMS has been proven to provide feedback reliably and promptly to ensure rapid protective action of a valuable asset.

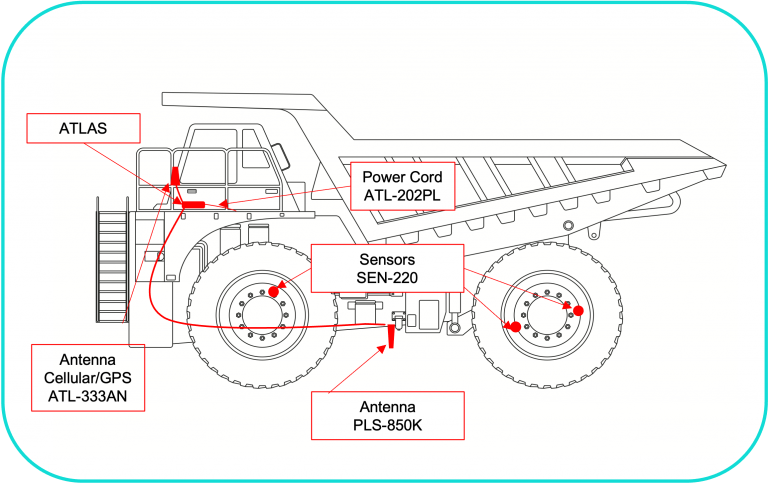

Fleet TPMS on a Dumper

ATLAS enables a fleet or site manager to measure the tire performance of the entire fleet via the ATLAS Insight web application.

Image Credit: Tough Tech

Image Credit: Tough Tech

Image Credit: Tough Tech

The following components would be required for an installation:

Table 1. Source: Tough Tech

| Part Number |

Description |

| ATLAS |

Fleet Gateway (ATLAS Griffin) |

| ATL-202PL |

ATLAS Power Lead |

| PLS-850K |

RF Antenna (to receive pressure readings from sensors) |

| ATL-333AN |

Cellular and GPS antennas |

| SEN-220 |

Industrial TPMS Sensors (mounted on the valve) |

Components for a Connected TPMS Solution

Connected installation on a Rigid Dump Truck. Image Credit: Tough Tech

It is recommended to add T-Valves to any SEN-220 Industrial Valve installation.

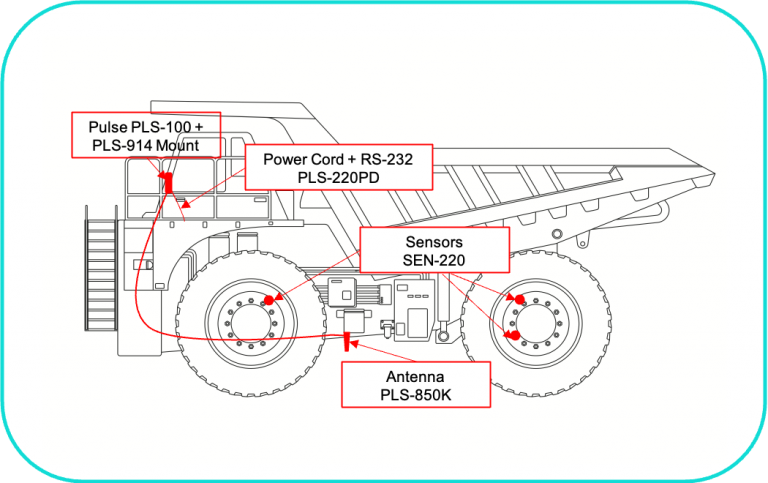

Stand-Alone TPMS on a Dumper

The stand-alone setup includes an in-cab screen/monitor for the driver to monitor tire temperatures and pressures. All alerts are visible to the driver instantly.

For a connected fleet version, use ATLAS.

Table 2. Source: Tough Tech

| Part Number |

Description |

| PLS-100 |

Pulse Monitor |

| PLS-220PD |

Pulse Power & RS-232 data cable |

| PLS-850K |

RF Antenna (to receive pressure readings from sensors) |

| PLS-914M |

Mounting kit for Pulse |

| SEN-220 |

Industrial TPMS Sensors (mounted on the valve) |

Components for a Stand-alone TPMS Solution

Stand-alone installation on a Rigid Dump Truck (RDT). Image Credit: Tough Tech

There are several support videos available that can assist in installing stand-alone TPMS.

It is recommended to add T-Valves to any SEN-220 Industrial Valve installation.

Table 3. Source: Tough Tech

| Examples of Manufacturers & Models |

| CAT: |

770, 772, 773, 775, 777, 785, 789, 793, 794, 796, 797, 798 |

| Komatsu: |

325, 405, 465, 605, 785, , 1500 |

| Volvo: |

R100E, R70D |

| Hitachi: |

3500, 4000, 5000 |

| XCMG: |

XDM91, XDE170, XDE240, XDE300 electric |

This information has been sourced, reviewed and adapted from materials provided by Tough Tech.

For more information on this source, please visit Tough Tech.