Sponsored by Tough TechReviewed by Louis CastelMar 24 2023

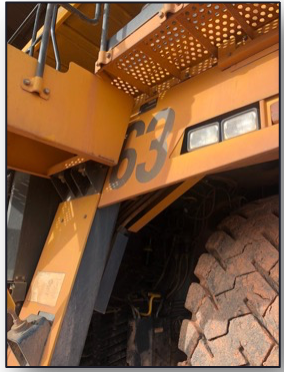

A site in Guinea, West Africa, was finding it challenging to maintain and recover its fleet of OTR 777E (Rigid Dump Truck) machines, challenges often found in remote and harsh environments. The innovative ATLAS TPMS technology was vital in ensuring the optimal performance and longevity of the machine’s tires.

Image Credit: Tough Tech

Image Credit: Tough Tech

The ATLAS OTR Tyre Pressure Monitoring System (OTR TPMS)

The tire pressures on the machine were set to 7.1 bar (102 psi) for all wheel positions. Maintaining close communication with the site personnel, the ATLAS service base in the UK could track and respond to any tire pressure-related issues that may have arisen. This collaboration facilitated several successful interventions by the ATLAS system, extending tire life and preventing catastrophic failure.

A Real-World Example

One such intervention was carried out when an “under pressure” alert was displayed for the Right Rear Inner (RRI) tire, registering 5.9 bar (86 psi), for which a notification was sent. Immediate action was required when a cross axle alert was triggered – even as the tire pressure continued to trend downwards.

Image Credit: Tough Tech

Meanwhile, the Left Rear Inner (LRI) tire lost 1.7 bar (24 psi) of pressure within 24 hours and showed an “under pressure” alert.

A subsequent loss of 0.9 bar (11 psi) in just 50 minutes indicated imminent catastrophic tire failure.

The ATLAS TPMS system intervened and saved the life of both the Right Rear Inner and Left Rear Inner tires, more than $20,000 in costs, and prevented significant downtime of the machine.

Continuous Monitoring and Real-Time Updates

The ATLAS system continued to monitor the site, giving real-time updates and advice on the fleet tires.

Image Credit: Tough Tech

The tires were maintained at their optimal working capacity. They were not impacted by severe underinflation, which would have decreased puncture resistance, reduced tire life, decreased safety and productivity, and increased fuel consumption.

Integrating real-time TPMS monitoring into maintenance best practices has improved response times and proactively prevented issues by utilizing machine feedback.

Benefits of TPMS

Image Credit: Tough Tech

Case Study OTR TPMS – Conclusion

The ATLAS TPMS solution was highly beneficial in reducing the cost of machine operation by saving tire life, reduced fuel consumption, improving resistance to punctures, and creating a safe working environment for site personnel. The ATLAS system also made it possible to avoid disruption to production by preventing tire failure on the machines, leading to approximately $20,000 saved in expenses.

Image Credit: Tough Tech

Recommendation

Given its proven results in the challenging environment of the Guinea site, the ATLAS 24/7 connected TPMS solution is highly recommended for fleet purchases. The solution includes a complete after-sales service, including online training and manuals, and the option for an Overwatch service to ensure the operator experiences the maximum benefits of the data insights that the ATLAS TPMS provides.

This information has been sourced, reviewed and adapted from materials provided by Tough Tech.

For more information on this source, please visit Tough Tech.