The global transition to clean energy is fueling demand for critical minerals, particularly copper. Meeting this demand has become more and more challenging due to declining ore grades, complex ore bodies, and tightening ESG regulations. Bulk ore sorting is one solution increasingly used to improve processing efficiency.

Bulk ore sorting is a preconcentration approach that helps miners maintain or increase head grade when processing heterogeneous ore bodies. By separating waste or below-grade material from material that can be blended, it allows operators to maintain a consistent, economically viable feed stream.

Effective bulk ore sorting can extend productive mine life, reduce the scale of new processing plants, and help lower the amount of energy, water, and tailings associated with producing each ton of useful material.

A high degree of ore body heterogeneity is crucial for effective bulk ore sorting. For assets that satisfy this requirement, sorting efficiency depends on accurately and precisely measuring the ore leaving the mine to distinguish waste from processable material reliably. The performance of the analyzer selected for this measurement is therefore critical.

Thermo Scientific™ CB Omni™ Agile Online Elemental Cross-Belt Analyzer. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Using PGNAA for Bulk Ore Sorting

Bulk ore sorting depends on sensing technology capable of:

- Representatively analyzing bulk material

- Differentiating processable ore from waste, in other words, differentiating ore that is above or below the required head grade.

Prompt Gamma Neutron Activation Analysis (PGNAA) is well-suited to these needs.

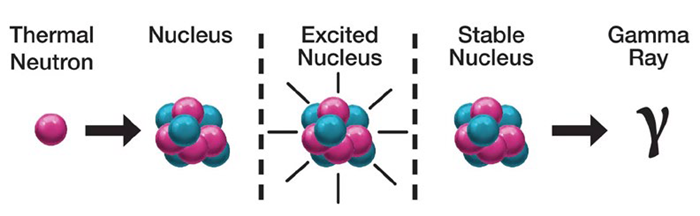

As a non-destructive method, PGNAA determines elemental composition by analyzing the gamma ray ‘signatures’ emitted when an atomic nucleus, excited by thermal neutron capture, returns to its ground state (see Figure 1)

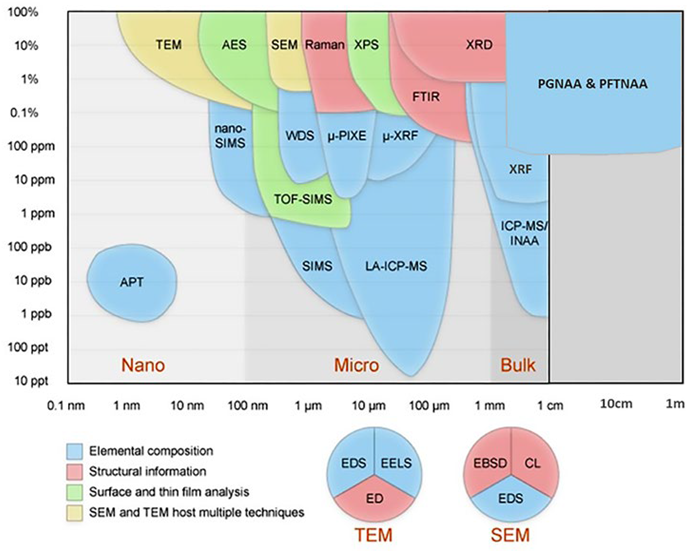

The neutrons used in PGNAA provide high penetration, and the resulting gamma rays have high transmission through the sample. Figure 2 compares the high penetrability of PGNAA with other analytical techniques by plotting penetrability (x-axis) against the relative detection capabilities (y-axis) of alternative methods.

PGNAA uniquely combines deep material penetration with sufficient sensitivity for bulk stream analysis, facilitating precise characterization of heterogeneous ore across the whole cross-section of the material.

Additionally, PGNAA is a rapid method that provides instantaneous measurement essential for responsive control. Continuous sorting based on such measurements allows miners to divert small increments of feed, rather than truckloads or shovel loads, thereby enhancing the sorting process accuracy.

Figure 1. Schematic illustrating the principle of measurement of PGNAA. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Figure 2. Performance characteristics (detection (y-axis) and penetration (x-axis)) for a range of analytical techniques highlight the unique suitability of PGNAA for bulk ore sorting. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Analyzer Performance

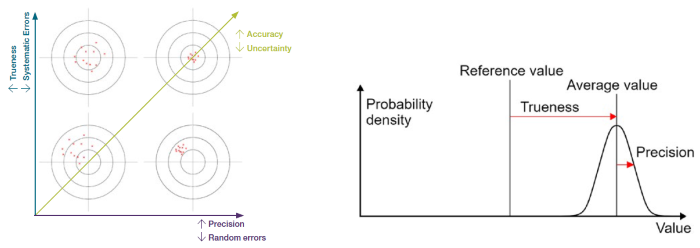

Both precision and accuracy must be evaluated when determining whether a PGNAA system is suitable for bulk ore sorting (see Figure 3).

Accuracy is a measure of agreement with a “true” or accepted reference value and is primarily affected by systematic errors; precision is a measure of agreement with other like measurements and is defined by the magnitude of random errors.

The Thermo Scientific™ CB Omni Agile™ Elemental Analyzer is engineered, configured, and calibrated to minimize both systematic and random errors, delivering excellent precision and accuracy for each application.

Figure 3. PGNAA systems may vary with respect to the accuracy or precision of measurements, or both. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

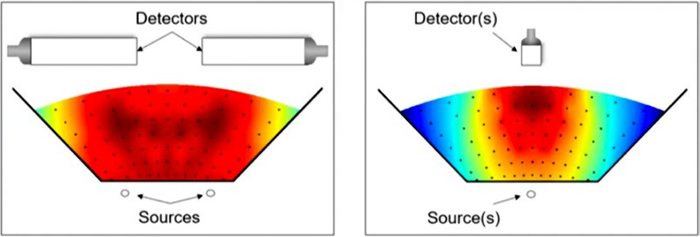

Measurement uniformity is the primary factor influencing the accuracy of online PGNAA systems (see Figure 4). While inherently heterogeneous, incoming ore may be prone to segregation. It is therefore critical to ensure consistent measurement across the belt, much like representative sampling, a prerequisite for any analytical measurement.

The CB Omni Agile Analyzer provides versatility in configuring both the neutron source (isotope (Californium 252, 252Cf) or electrical neutron generator) and the detector volume to optimize measurement uniformity and reduce systematic error.

A stringent factory calibration process that spans the entire range of expected ore compositions and belt loading conditions further ensures accuracy.

In terms of precision, this is mainly determined by the number of detected neutron interactions, making both neutron output and detection capability crucial. The CB Omni Agile Analyzer supports up to 78 μg of 252Cf – more than any other PGNAA system currently available – enabling enhanced neutron flux and increased measurement precision.

In addition, it uses larger volume NaI scintillation crystals (up to 12 times larger than commercial alternatives) to improve detection. This combination of high neutron generation and effective detection of the resulting gamma rays gives the CB Omni Agile Analyzer market-leading precision for a given mass loading and measurement duration.

Figure 4. Uniform measurement is crucial for accurate PGNAA. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Comparing Performance

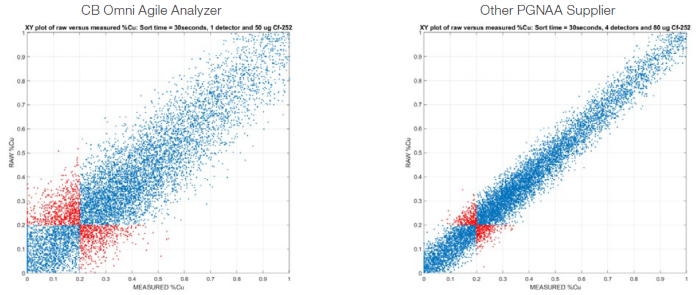

Figure 5 demonstrates the direct correlation between performance characteristics and bulk ore sorting efficiency. The right area shows a simulated dataset from a PGNAA system equipped with a single detector and a 50 μg 252Cf source; the left area displays comparable data for a CB Omni Agile Analyzer with four detectors and a 78 μg 252Cf source.

Red data points indicate misclassified material – either waste processed as ore (false positives) or ore discarded as waste (false negatives). These misclassifications directly reduce process efficiency and resource recovery.

Processing ore with Cu below the specified cut-off value lowers process efficiency, while underestimating Cu content results in valuable ore going to waste. Both effects directly affect the bottom line.

By reducing the frequency of inaccurate ore characterization, the CB Omni Agile Analyzer minimizes head grade variability, facilitating more stable, predictable, and controllable downstream mineral separation processes, while reducing the loss of valuable material and process capacity spent processing waste and below-cutoff material.

Figure 5. Measurement accuracy and precision directly impact the efficiency of bulk ore sorting. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Conclusion

Bulk ore sorting is a valuable pre-concentration approach for miners seeking to increase output, maximize asset value, and minimize environmental impact. Success depends on sensing technology able to perform representative, reliable bulk feed flow characterization and robustly distinguish below-grade material from material that can be profitably processed.

Utilizing the powerful PGNAA method, the CB Omni Agile Analyzer provides instantaneous elemental analysis, essential for supporting high-efficiency bulk ore sorting.

Its high precision and accuracy minimize both false acceptances and false rejections, enhancing asset utilization and minimizing the processing of sub-economic material.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.