The majority of natural ore deposits do not contain high concentrations of minerals or metals, making ore grading and mineral concentration necessary to produce final metal products from the original raw material.

While handheld X-ray fluorescence (XRF) analysis can be easily applied to determine elemental constituents for most low-concentration natural samples, its use in concentrated ore samples can be more challenging.

Handheld XRF Analyzers in Mining

Handheld XRF is capable of delivering rapid and precise elemental analysis results with minimal or no sample preparation across multiple phases of mining activity, from grassroots exploration to exploitation, ore grade control, and even environmental investigations.

Thermo Scientific™ Niton™ handheld XRF analyzers are widely used in the global mining industry to measure elements ranging from magnesium (Mg) to uranium (U). Niton XRF analyzers provide exceptional limits of detection (LOD), high accuracy across a broad sample range, and significant enhancements related to data acquisition speed.

Application

Following identification and extraction, ore minerals are frequently concentrated using various methods that leverage both characteristics, including mechanical separation techniques such as screening and chemical separation methods like flotation and acid leaching.

These processes produce a uniform and homogeneous mineral concentrate with relatively simple composition/mineralogy.

Niton XRF analyzers include a feature called User Method, also known as User Mode, which employs empirical calibration. This approach is advantageous when evaluating concentrated samples of heavy metals.

Note: Homogeneous sample concentration must be verified for this application.

It should be noted that the Fundamental Parameter (FP) factory mode is a general-purpose mode that is well-suited for various sample types.

The FP mode is also “standardless” and does not require known samples to obtain quantitative results. However, in processed samples with very high metal concentrations, the concentration of the metal of interest is, in some cases, reported as less than its true value if the regular FP mode is used.

To obtain precise quantitative results for these samples, the UserMethod is recommended. In this approach, samples are evaluated, and the signals are reported as intensity (counts per second per microampere). Calibration curves are subsequently plotted based on known concentrations (from laboratory values) and intensity (from HHXXRF results).

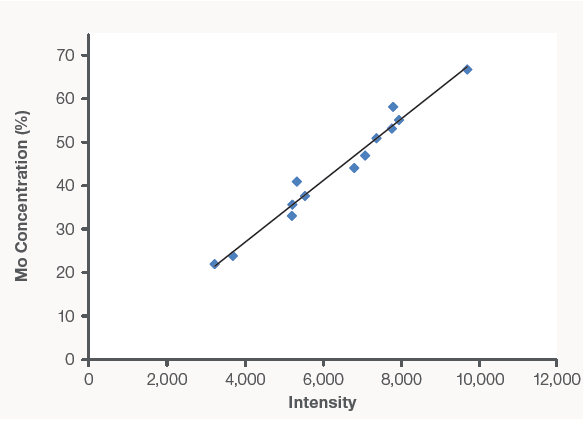

The equation derived from the trend line in the graphs in Figure 1 is used to convert HHXRF readings in unknown samples from intensity to elemental concentrations in weight percent or parts-per-million.

Figure 1. Example of the generation of a calibration curve. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Method

This research employed the UserMethod on a Thermo Scientific™ Niton™ XL3t GOLDD analyzer on molybdenite (MoS2) concentrate samples. Ore grades in these concentrates can range from 25 % to 65 % Mo.

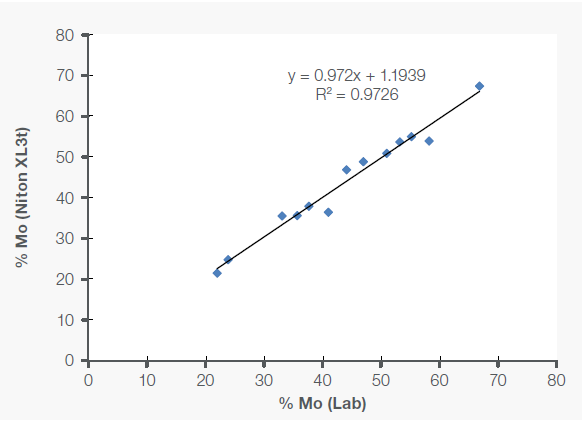

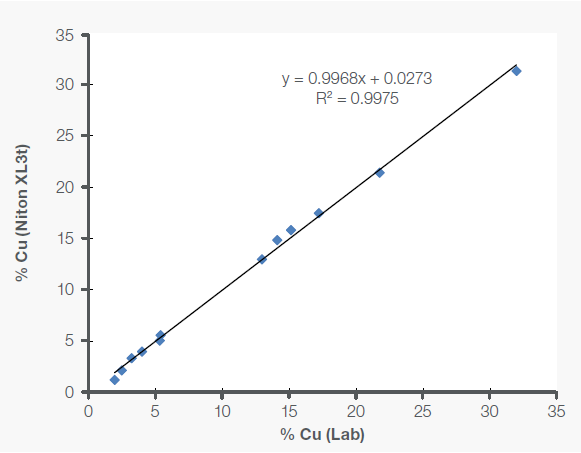

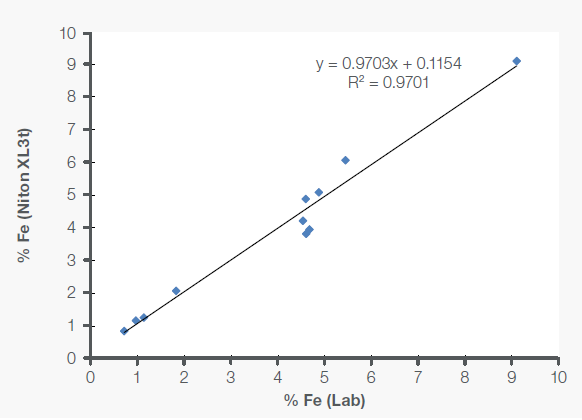

Figure 2 presents concentrations of molybdenum (Mo), copper (Cu), and iron (Fe) in these concentrates, along with correlation to laboratory assay data.

Results

The coefficient of determination, the R2 value, indicates how well the datasets correlate, with an R2 value of 1 representing perfect correlation. The correlation values for Mo, Cu, and Fe are 0.97, 0.99, and 0.97, respectively (see Figure 2).

When the value of the slope next to "x" in the trendline equation differs significantly from 1, it indicates the presence of systematic errors, also called biases. Since all three elements exhibit values between 0.95 and 1.05, the biases are low and the measurements are accurate.

Figure 2. Correlation of Mo, Cu, and Fe data between portable XRF and lab in molybdenite (MoS2) concentrate samples. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Conclusions

HHXRF is a highly dependable and effective instrument for analyzing all mining and metal sample types, from the exploration stage (low grade) to the ore grading stage (high grade).

For concentrated heavy-metal mineral samples, the UserMethod provides an alternative to the standardless fundamental parameter calibration approach and can yield more precise results in cases such as molybdenum or lead concentrates. Once a UserMethod is uploaded, results are displayed directly on the analyzer, providing immediate information needed to maintain accurate production-line grade control.

Special thanks to Freeport-McMoRan Copper & Gold, Inc., for their collaboration and for providing the analyzed samples.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.