The ZSX Primus III NEXT performs rapid elemental analysis and quantification of main and trace elements (4Be to 96Cm). Its high throughput, great sensitivity, and low cost make it a perfect choice for industrial applications.

Key Features

- High throughput: Provides accurate results in minutes

- High-end WDXRF: Perfect for industrial applications

- Extended detection range: Be to Cm

- ZSX Guidance software: Enhances usability and assists with calibrations

- Tube-above optics: Eliminates particulate contamination, ensuring consistent, reliable results

- Attractive pricing: WDXRF performance at an affordable price

Tube-Above Optics

Rigaku’s unique tube-above optical configuration prevents dust and particles from contaminating optical components and distorting readings while decreasing maintenance and maximizing uptime. As a result, it is perfect for analyzing pressed powder samples. Moreover, wavelength-dispersive X-Ray fluorescence (WDXRF) outperforms energy dispersive X-Ray fluorescence (EDXRF) regarding spectral resolution.

Improved Quality of Analytical Results

The ZSX Primus III NEXT incorporates several significant improvements over its predecessor, resulting in improved results and higher throughput levels. These include:

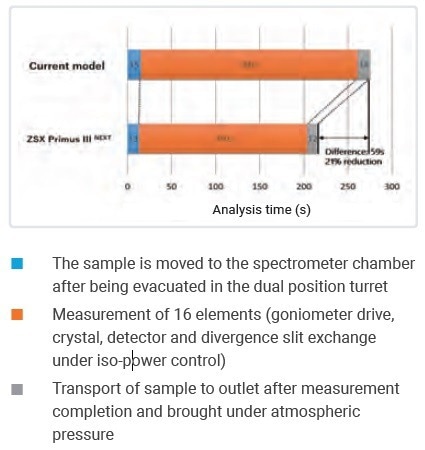

- Using a digital multi-channel analyzer (D-MCA) and effective control of each drive unit increased quantitative analysis throughput by 21%.

- An S-PC LE is a gas-shielded proportional detector for light elements that is environmentally beneficial. The S-PC LE eliminates the need for a detection gas cylinder.

- Powerful ZSX Guidance software, shared by Rigaku's flagship WDXRF spectrometers, has a scheduling function to automate and streamlines operations.

Overview of the Main Features and Benefits

- High-end WDXRF spectrometer for industrial environments: Cutting-edge industrial spectrometer for more harsh operating conditions

- Enhanced reliability due to tube-above configuration: Less risk of spectrometer contamination increases uptime

- Extended analytical flexibility: Full elemental analysis (4Be to 96Cm)

- ZSX Guidance software: No need to be a specialist. Incorporated intelligence assists with calibration development

- High-speed analysis: Accurate and precise results in minutes allow real-time process control

- Attractive pricing: All this for an affordable price

- Enhanced service and application support: Rigaku is a trusted partner

- Data sharing: Makes it possible to have the Rigaku spectrometers in all the laboratories operating on the same calibrations

Image Credit: Rigaku Corporation

Image Credit: Rigaku Corporation

Image Credit: Rigaku Corporation

Main Markets and Pre-Calibration Packages

The primary application of WDXRF is to determine the composition of samples that are either raw materials, intermediates, or finished products. Specific industrial markets make extensive use of XRF technology. The ZSX Primus III NEXT is well-suited for the following applications:

- Mining and minerals: The different kinds are typically raw materials for other industries. The analysis of main and minor oxides and trace elements may be necessary depending on the goal. The dedicated pre-calibrated methods OXIDE-FB-PAK and GEO-TRACE-PAK have been formulated to improve the needs of such applications.

- Cement: This industry requires constant monitoring of raw materials, raw mix, clinker, and cement samples. High sample throughput and short analysis times are frequently required. The OXIDE-FB-PAK eliminates the need to create numerous calibrations for each sample type.

- Steels and metals: Many metals and alloys are manufactured for several uses. The company provides application packages for the following metal groups: stainless steel, low alloy steel, FeNiCo-based alloys, and ferroalloys.

- Petrochemicals/Polymers: It is difficult to envision a world without plastics. The concentration of additives and contaminants in various polymers can be determined using WDXRF.

- Chemicals: Hundreds of chemicals, many of which are derived from minerals, are manufactured daily and are subject to quality control. WDXRF is a primary method used to guarantee the quality of these products. Rigaku can assist users in locating a suitable set of calibration standards.

- Ceramics and refractories: Check the composition of raw materials which can directly influence final products. Similarly, confirm the composition of the final product to ensure it will perform in service.

- Glass manufacturing: Ideal for monitoring the composition of raw materials.

- Environmental: Check for contaminants e.g. heavy metals in soils at trace levels.

Image Credit: Rigaku Corporation

Image Credit: Rigaku Corporation

Hardware Features and Benefits

Tube-Above Optics

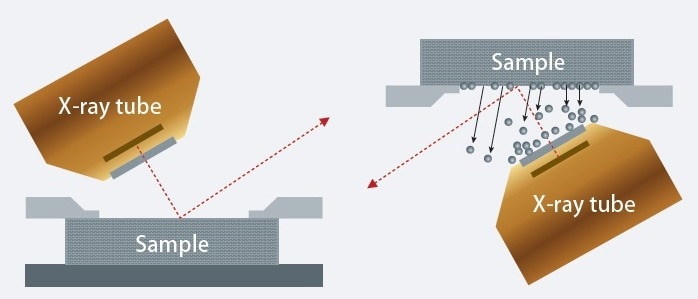

In high-precision analytical instruments, there is always the risk that an untrained operator would harm the spectrometer. The equipment is safe with the ZSX Primus III NEXT even if a pressed pellet cracks inside the spectrometer due to its tube-above optics.

Image Credit: Rigaku Corporation

Avoid powder spills into the optical chamber. Tube above optical configuration (left) vs. tube below (right). Image Credit: Rigaku Corporation

Sample Throughput

Sample throughput has been enhanced by:

- Multi-tasking control of drive units

- High-speed data processing

For instance, consider the quantitative examination of 16 constituents in a cement sample. Time can be saved by roughly 21% compared to the prior model.

Image Credit: Rigaku Corporation

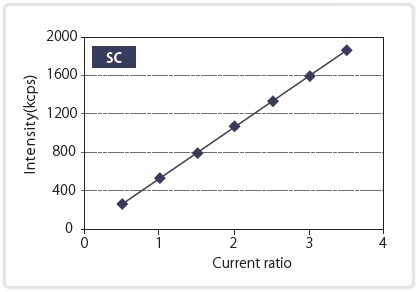

Improved Precision Through Higher Counting Linearity

A DMCA (Digital Multi-Channel Analyzer, 1024 channels) allows faster data collection and processing. High-speed digital processing boosts analytical accuracy by enhancing counting linearity and maximum counting rate (linearity: less than 1% relative error)

- Scintillation counter 1800 kcps

- Gas-sealed proportional counter 3000 kcps

- Gas flow proportional counter 3000 kcps

Image Credit: Rigaku Corporation

Gas-Free Installation Possible

Optional gas-sealed proportional counter for light element analysis (S-PC LE):

8O–28Ni

- In case P10 gas is difficult to obtain

- Simpler, gas-free installation

Image Credit: Rigaku Corporation

Software Features and Benefits

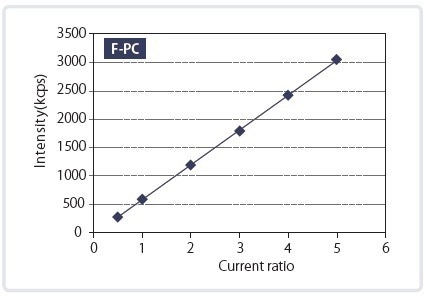

ZSX Guidance Software

- Strong user support, including generating measurement conditions and calibration aid for experienced and novice WDXRF users.

- User-friendliness is ensured by integrated software for day-to-day analysis and service or maintenance.

- Customize software access authorization levels based on operator experience to prevent unintentional software misuse and to prevent calibration parameters from being modified.

- SQX is a powerful standardless FP software suite for analyzing fully unknown samples.

Flow Bar Scheme

The flow bar allows for intuitive application creation and configuration.

Image Credit: Rigaku Corporation

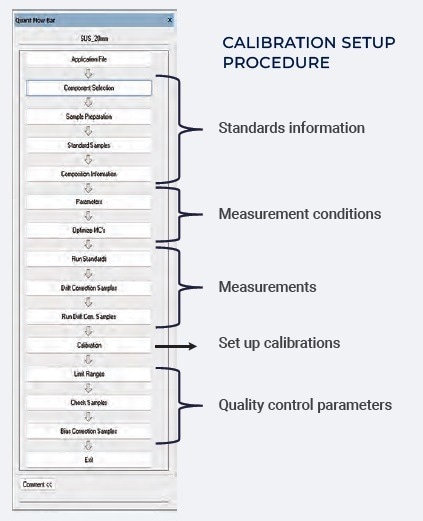

Improved Reliability of Analytical Results

Next to the analytical result is the estimated standard deviation from a single measurement:

Image Credit: Rigaku Corporation

The following table displays the estimated standard deviation from a single measurement to the standard deviation from 10 repeated measurements. The estimated and observed standard deviations are quite close.

Table 1. Source: Rigaku Corporation

| |

|

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

| single measurement |

analysis result |

1.202 |

0.020 |

0.008 |

0.908 |

15.18 |

15.77 |

0.470 |

| Std deviation |

0.0023 |

0.0004 |

0.0003 |

0.0030 |

0.0088 |

0.0117 |

0.0008 |

| 10 repeated measurements |

average analysis result |

1.205 |

0.020 |

0.007 |

0.905 |

15.18 |

15.76 |

0.471 |

| Std deviation (actual) |

0.0027 |

0.0002 |

0.0001 |

0.0030 |

0.0082 |

0.0077 |

0.0006 |

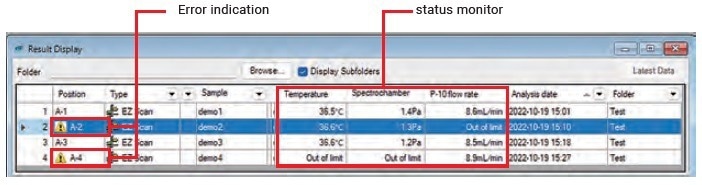

Spectrometer Parameters in Results View

- The status of the X-Ray spectrometer’s physical characteristics, such as vacuum, temperature, and detector gas flow rate, can have a significant impact on analytical results.

- The ZSX software results display shows the most critical parameters and a hardware error message is provided.

- Verify analysis results quickly when a parameter is out of specification.

Image Credit: Rigaku Corporation

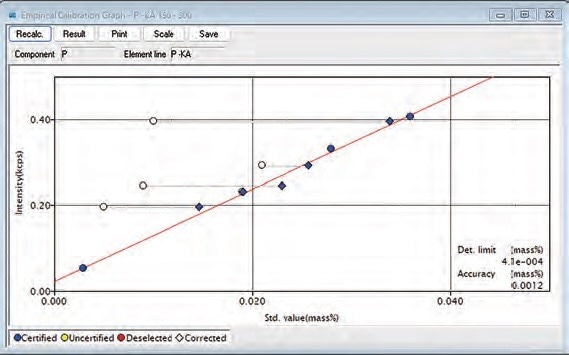

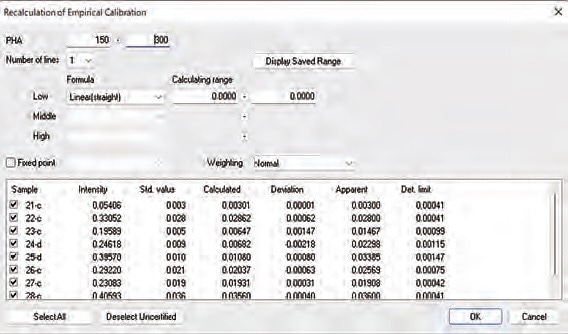

Automatic Calculation of Detection Limits

- The calibration curve immediately displays the Lower Limit of Detection (LLD), calculated using the measurement conditions.

- The LLDs for each standard are calculated while accounting for spectral interferences.

- LLDs are also listed as a “Det. Limit” in the results display window.

Image Credit: Rigaku Corporation

Image Credit: Rigaku Corporation

User Access Level Setting

Setting access levels for operators to prevent human errors:

- Calibration changes or deletions

- Analytical results editing

- Unwanted service activities

Certain software functionalities will be available depending on the user-level setting:

Full menu. Image Credit: Rigaku Corporation

Routine analysis. Image Credit: Rigaku Corporation

ZSX Guidance logon window. Image Credit: Rigaku Corporation

Time-Saving Daily Analysis Management Tool

Image Credit: Rigaku Corporation

Scheduler function:

- Automatic start-up of the spectrometer

- X-rays on

- Aging

- PHA measurement

- Automatic Quality Check (QC) and Drift Correction (DC)

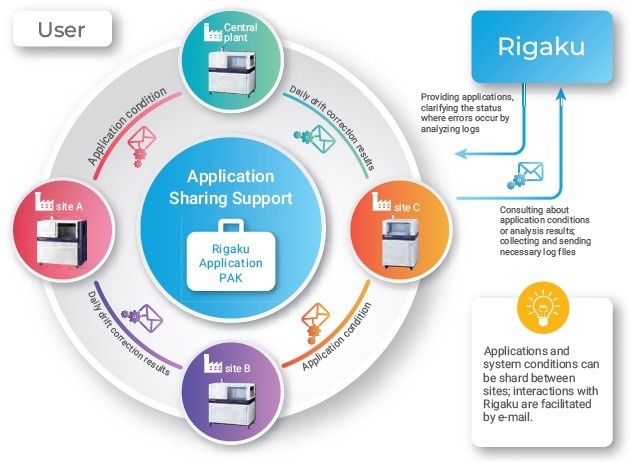

Application Sharing and Support

Image Credit: Rigaku Corporation

Plants with similar X-Ray spectrometers can share applications between systems

- Knowledge transfer

- Increased productivity by lowering the workload of less experienced users

The data pack function simplifies testing analysis methods, examining error log files, and monitoring spectrometers from remote locations.

Specifications

Table 2. Source: Rigaku Corporation

| ZSX Primus III NEXT |

| Analytical range |

8O - 96Cm standard (4Be - 96Cm Optional*1) |

| Spectral method |

Wavelength dispersive |

| Atmosphere |

Vacuum |

| X-ray generator system |

X-ray tube |

End window type Rh target 3 kW |

| High voltage generator |

High-frequency inverter system |

| Heat exchanger |

Pure water circulation supplier (built-in) |

| Spectrometer |

Irradiation method |

Tube-above |

| Sample changer |

Expandable sample changer with up to 48 positions |

| Sample inlet |

Air lock system |

| Maximum sample size |

∅ 52 mm — 30 mm (H) |

| Primary filter |

Ni400, Ni40, Al125, Al25 |

| Analysis area diaphragm |

4 sizes automatic exchange mechanism 35, 30, 20 and 10 mm |

| Primary Soller slit |

3 positions automatic exchange machanism

Standard and fine slits / Optional: Ultralight element slit |

| Goniometer |

θ-2θ¸ independent driving mechanism |

| Continuous scan |

0.1°~240° /min |

| Crystal exchanger |

10 crystal automatic exchange mechanism |

| Analyzing crystal |

Standard: LiF, 200, PET, RX26

Optional: Ge, LiF, 420, LiF(220), RX9, RX4, RX35, RX40, RX45, RX61, RX61F, RX75 |

| Vacuum system |

One shared vacuum pump between sample- and analyzing chamber.

Sample powder trap filter |

| Counting system |

Pulse height analyzer |

Digital multichannel analyzer (DMCA) |

| Detector |

SC (Scintillation counter)

F-PC (Gas flow proportional counter)

Optional: S-PC LE (Gas sealed proportional counter: does not require P-10 gas) |

*1 depending on crystal configurations

Installation Requirements

Table 3. Source: Rigaku Corporation

| . |

| Required power supply |

Instrument: Single (200 - 240 V), three phase (200 V) 50/60 Hz 40A

Personal computer: 1-phase, 100-240 V, 10A |

| Grounding specification |

30 Ω or below grounding (independent) |

| Cooling water |

Temperature: Lower than 30 ºC Pressure: 0.29 - 0.49 MPa Flow: More than 5 l/min Quality: Equivalent to drinking water |

| Drained water |

Gravity drain |

| Room temperature |

18 - 30 ºC Daily variation within ±2 ºC |

| Relative humidity |

75% RH or less |

| Vibration |

Less than 2 m/s2 Not detectable by a human |

| Gas for detector |

P10 Gas (argon 90% methane 10% mixed gas). Pressure 0.15 MP a, 7 ml/min. Not required if S-PC LE is selected |