Locksley Resources Ltd (“Locksley”) is pleased to advise results from initial metallurgical testwork completed by the Company on samples collected from the Desert Antimony Mine (“DAM”) Prospect, validating that the Mojave Project can deliver the feedstock required to underpin a domestic mine-to-market antimony supply chain. Recovery rates of this level confirm Locksley’s pathway to 100 % Made in America Antimony, directly aligned with U.S. government priorities for onshore critical mineral supply security.

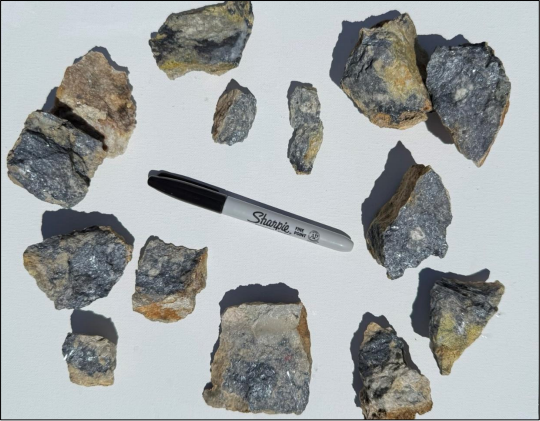

Figure 1. Photo of small subset of the 23.1 kg composite sample collected for metallurgcal testwork. Light grey mineral is stibnite (antimony sulphide). Composite average sample grade is 9.6 % Sb. Image Credit: Locksley Resources Ltd

Figure 1. Photo of small subset of the 23.1 kg composite sample collected for metallurgcal testwork. Light grey mineral is stibnite (antimony sulphide). Composite average sample grade is 9.6 % Sb. Image Credit: Locksley Resources Ltd

Metallurgical Testwork Program

Locksley engaged specialist metallurgical consultants SGS Australia owned Independent Metallurgical Operations Pty Ltd (IMO) to oversee an initial metallurgical testwork program on a 23.1 kg composite sample grading 9.6 % antimony (“Sb”), collected from surface stocks at DAM (Figure 1). The composite sample was delivered to Base Metallurgical Laboratories located in Tucson Arizona for the planed testwork.

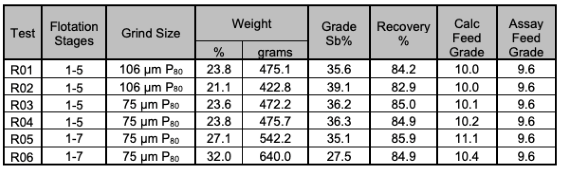

A standard flowsheet was devised by IMO to undertake a series of six flotation tests using a variety of reagents and initial rougher stage flotation steps, conditioning time and grind sizes. The results from each of the tests are shown on Table 1.

Table 1. Results from each of the six metallurgical tests conducted on composite sample collected from the Desert Antimony Mine Prospect. Further detail provided in Appendix A.

In all tests, the flotation proved effective in recovery of Stibnite (the antimony hosting mineral) from the composite sample and importantly produced a concentrate exceeding 30 % Sb in 5 out of the 6 tests completed. Furthermore, initial stage 1 steps delivered a high grade concentrate up to 59.6 % Sb (R04- stage 1), indicating that the antimony minerals liberate naturally from the initial grind, with rougher concentrate regrinding and cleaning expected to achieve a high-grade concentrate at high Sb recovery. This is significant as the testwork has demonstrated the potential to produce a high grade concentrate which could meet required specifications as feedstock material for conventional pyrometallurgical process.

Further testwork is ongoing with the objective of improving stibnite recovery and concentrate grade. It is anticipated that this will be achieved with subsequent regrind and cleaning stages with the goal of targeting a final concentrate grade of >50 % Sb (note pure stibnite has a theoretical grade of 71.68 % Sb).

Next Steps

Metallurgical testwork is ongoing and the following activities are planned or underway:

- Further regrind and cleaning testwork to determine overall recovery and concentrate grade

- Mineralogical testwork on the head, concentrate and tail to determine stibnite deportment to develop an understanding of the ore characteristics

- Provide a sample of concentrate to Rice University to commence with Dep Eutectic Solvent extraction testwork using DeepSolv™ methodology

- Investigate options to use the concentrate in a pilot test to produce antimony metal ingot, antimony oxide and antimony trisulphide

Julian Woodcock, Technical Director of Locksley Resources, commented: “This is an excellent milestone to have achieved for the Mojave Project, which demonstrates that conventional flotation technology is suitable to produce a stibnite concentrate from the Desert Antimony Mine Prospect. What is also remarkable is the success of the testwork on surface samples, which have been susceptible to oxidation. I am extremely encouraged by the results and optimistic that with further testwork we will be able to improve on this already high-quality first-pass outcome. This activity continues to rapidly advance our strategy to provide onshore supply of antimony to the U.S. market.”