Following an extensive evaluation program with AXT’s Automated Mineralogy Incubator, Larvotto Resources have become the first Australian mining company to install an Elemission ECORE. The ECORE rapid core scanner has been installed at their Hillgrove Antimony-Gold Project. The ECORE, acquired from ELEMISSION’s Australian distributor AXT, gives them near real-time analysis of drill cores from their drilling programs. This enables them to streamline geological logging and better target exploration programs as well the ability to optimise their geometallurgical workflows.

The Elemission ECORE rapid core scanner. Image Credit: AXT

The Elemission ECORE rapid core scanner. Image Credit: AXT

The Elemission ECORE uses laser ablation and atomic emission spectroscopy to rapidly scan up 1,000 metres per day of drill core and other geological materials. It is possible to generate a full elemental breakdown for every spot scanned, at spatial resolutions as fine as 50 microns. This allows users to identify mineralised zones, alteration halos and key textural relationships crucial for understanding ore continuity and zonation.

Larvotto worked extensively with AXT’s mineralogical services business, the Automated Minerology Incubator (AMI), their team of mineralogists and other multiscale mineralogy techniques. They were able to create detailed mineral libraries for the Hillgrove Mining project which enabled more accurate discrimination of mineralised zones. This information was critical to gaining a better understanding of the best exploration strategies, helping them map extensions of the deposit and assisting in the development of a robust and optimised geometallurgical flowsheet.

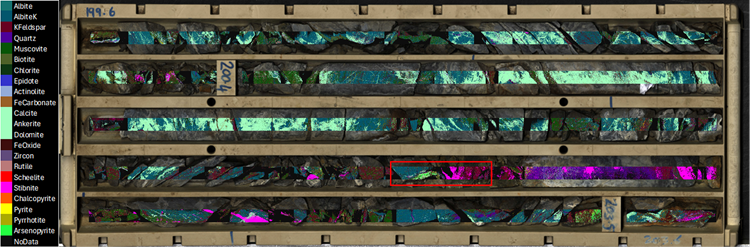

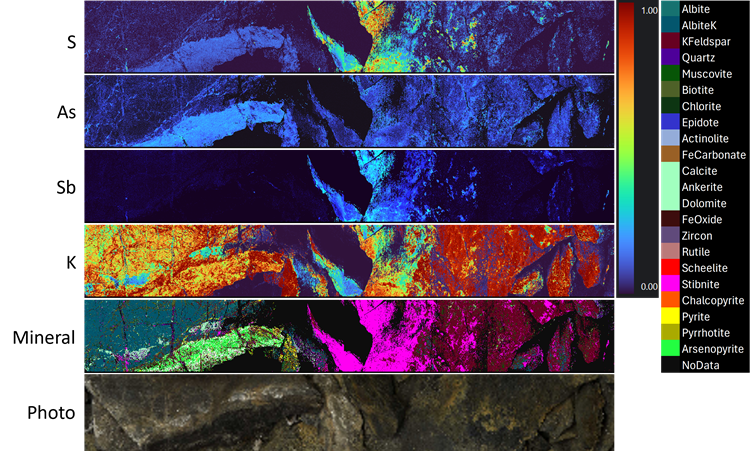

Tray of 1 m long drill core samples (above) with ECORE mineral maps overlaid and area of interest indicated in the red rectangle. Higher resolution mineral ECORE maps of a selected area of interest 20 mm x 150 mm (below). Image Credit: AXT

In addition to the AMI’s mineralogical expertise, Larvotto also utilised numerous cutting-edge techniques to complete detailed feasibility studies. Collectively, insights from all these channels targeted flowsheet improvements and enhanced overall recovery strategies.

- ECORE core scanning – allowing quantification of mineralogical phases.

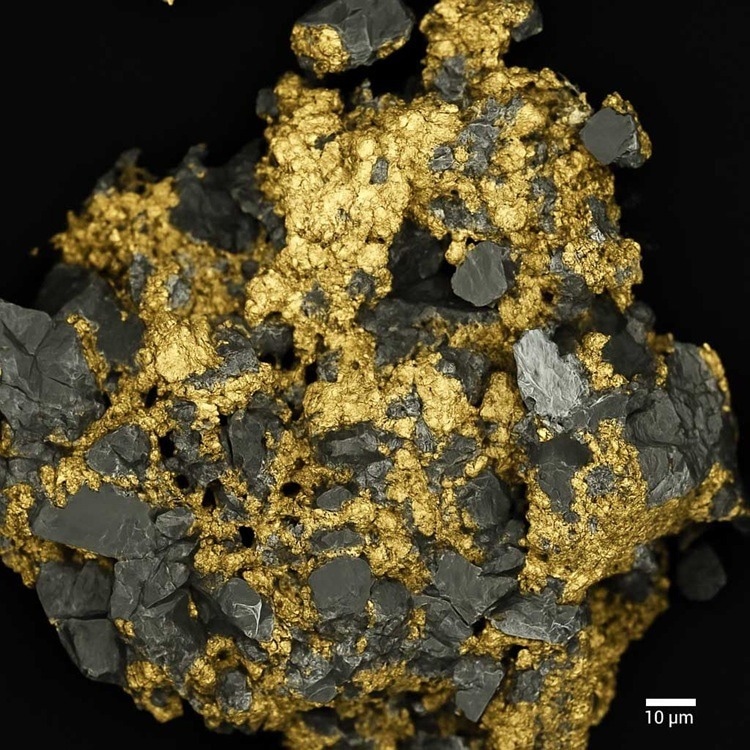

- TESCAN Integrated Mineral Analyser (TIMA) – enabled accurate identification and quantification of stibnite grain size as well as gold and antimony associations which feeds back into flowsheet development

- Comprehensive gold deportment analysis – to accurately predict gold and antimony distributions

TIMA analysis also identified the need for the introduction of rougher floatation and regrinding steps to more efficiently liberate target mineral species. Furthermore, analysis of rougher tails from early-stage tests underscored the necessity for reagent scheme optimisation.

Gold particle with stibnite intergrowth (antimony sulphide) analysed using TESCAN TIMA. Image Credit: AXT

The Elemission ECORE has been installed in a newly established facility in Armidale NSW and will be used to support exploration and metallurgical development activities at the Hillgrove Mine site. More specifically, in exploration it will provide multi-element and mineral map data, streamline geological logging and targeting, optimise sample selection, and build a digital geological library. In metallurgy, Larvotto will use the technology for pre-feasibility and metallurgical testing, optimising grinding and liberation, and troubleshooting process control.

Ron Heeks, Managing Director from Larvotto commented, “working with AXT and their mineralogists at the AMI showed us the value of logging standardised quantitative mineralogy data. Utilising their mineralogy services and experience with the technology, we were able to prove up the business case for having an instrument onsite. As the experts in the technology, we continue to work with the AMI to curate the data and ensure we get the best out of the technology.”

Richard Trett, AXT’s Managing Director added, “We are also excited in the vision Larvotto have shown. Through the adoption of Elemission’s ECORE technology, Larvotto have acquired near real time characterisation of an extremely complex mineralogical system allowing the optimising of the metallurgical processing and accessing potential recovery strategies not possible in the previous iteration of the Hillgrove Mine

We are equally excited to announce that we will be establishing an AMI operation in Armidale NSW to provide ongoing support to Larvotto’s Hillgrove Antimony-Gold Project, as well as providing access to the same technology to others in the Armidale region and the east coast of Australia regions.”

Studies performed by the AMI demonstrated how detailed, early-stage mineralogical characterisation can drive smarter processing decisions and decrease the risk of flowsheet development. Furthermore, the Larvotto owned Hillgrove Mines Antimony-Gold project highlights the value of modern mineralogical tools in unlocking the full potential of complex polymetallic ores and their critical role in guiding successful project development.

If you are a mine site committed to using the latest technology to more accurately characterise your ore deposit so that you can improve recovery using data driven decisions, you can access the same automated mineralogy technology and expertise through the AXT and the AMI.