From Mining to Shipping There is Always a Welding Alloys Solution

Mechanical bucket. Image Credit: Welding Alloys Ltd

Bulldozer. Image Credit: Welding Alloys Ltd

Carrier roller. Image Credit: Welding Alloys Ltd

Hammers. Image Credit: Welding Alloys Ltd

Internally cladded elbows. Image Credit: Welding Alloys Ltd

Tubes. Image Credit: Welding Alloys Ltd

Chute. Image Credit: Welding Alloys Ltd

Cone refurbishment. Image Credit: Welding Alloys Ltd

Dynamic classifier. Image Credit: Welding Alloys Ltd

Front impact plate. Image Credit: Welding Alloys Ltd

Transport pipes. Image Credit: Welding Alloys Ltd

Screw. Image Credit: Welding Alloys Ltd

Welded bucket edge. Image Credit: Welding Alloys Ltd

Coal conveyor. Image Credit: Welding Alloys Ltd

Reclaimer bucket. Image Credit: Welding Alloys Ltd

Sieve. Image Credit: Welding Alloys Ltd

ID-Clad Tubes. Image Credit: Welding Alloys Ltd

Segment of a cone housing. Image Credit: Welding Alloys Ltd

Driller. Image Credit: Welding Alloys Ltd

Gyrator. Image Credit: Welding Alloys Ltd

Cone construction. Image Credit: Welding Alloys Ltd

Distributor. Image Credit: Welding Alloys Ltd

Valves. Image Credit: Welding Alloys Ltd

Chutes. Image Credit: Welding Alloys Ltd

Welding Alloys Ltd provides a series of hard plates engineered to offer repair and refurbishment solutions for several wear-related issues that occur in the mining industry. All products from Welding Alloys Ltd are user-friendly and offer high flexibility, making them the best solution for an extensive range of applications in situ or in the repair shop.

WA Integra™

WA Integra provides novel rebuilding and hardfacing solutions through a worldwide network of service centers or in situ.

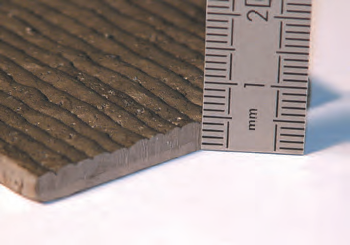

Hardplate™: Heavy-duty Composite Wear Plate

- Sought-after maintenance solution

- Coating thicknesses and base metal can be chosen based on the application

- Multiple coating types can be selected

Image Credit: Welding Alloys Ltd

Image Credit: Welding Alloys Ltd

Hardlite™: Ultra-thin Composite Wear Plates—Less than 5 mm

- Harder and lighter than other similar hard plates

- Engineered for applications where weight is a problem

- Beneficial for moving parts

Image Credit: Welding Alloys Ltd

Tuffplate™: Impact-Resistant Wear Plates

- Best solution for material transfer and transportation sectors

- Developed for applications prone to a combination of wear and impact

Image Credit: Welding Alloys Ltd

Cladded Tubes

- Come in a range of internal diameters starting from 40 mm

- Tailor-made diameters with ultimate abrasion resistance

- Internally cladded tubes endure high levels of abrasion

- Manufactured in Welding Alloys’ Integra service centers with the company’s 3D-Touch MultiSurfacer machine

- Standard and elbow pipe solutions can be supplied.

Image Credit: Welding Alloys Ltd

A Perfectly Controlled Technology

WA Integra™ Services

Novel hardfacing and rebuilding solutions are offered by welding.

Image Credit: Welding Alloys Ltd

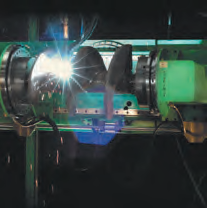

WA MultiSurfacer™

Welding Alloys engineers and manufactures automated welding equipment for hardfacing and rebuilding applications.

Image Credit: Welding Alloys Ltd

WA Cored Wires™

Cored welding wires of all types are designed and manufactured by Welding Alloys Ltd.

Image Credit: Welding Alloys Ltd

This information has been sourced, reviewed and adapted from materials provided by Welding Alloys Ltd.

For more information on this source, please visit Welding Alloys Ltd.