Mining Waste and Its Significance

A Brief Overview of Types and Forms of Mining Waste

Challenges of Mining Waste

Reducing Mining Waste: A Brief Overview

How are Sensors Being Used to Reduce or Eliminate Mining Waste?

Uses of Mining Waste in Road Construction

What Does the Future Hold?

References and Further Reading

Mining plays a critical role in the global economy, allowing us to extract and use rare earth minerals such as lithium for a wide range of applications, including electric vehicle batteries and energy storage systems. At the same time, mining operations produce substantial waste - tailings, waste rock, slag, contaminants, and harmful emissions - that pose environmental and operational challenges.

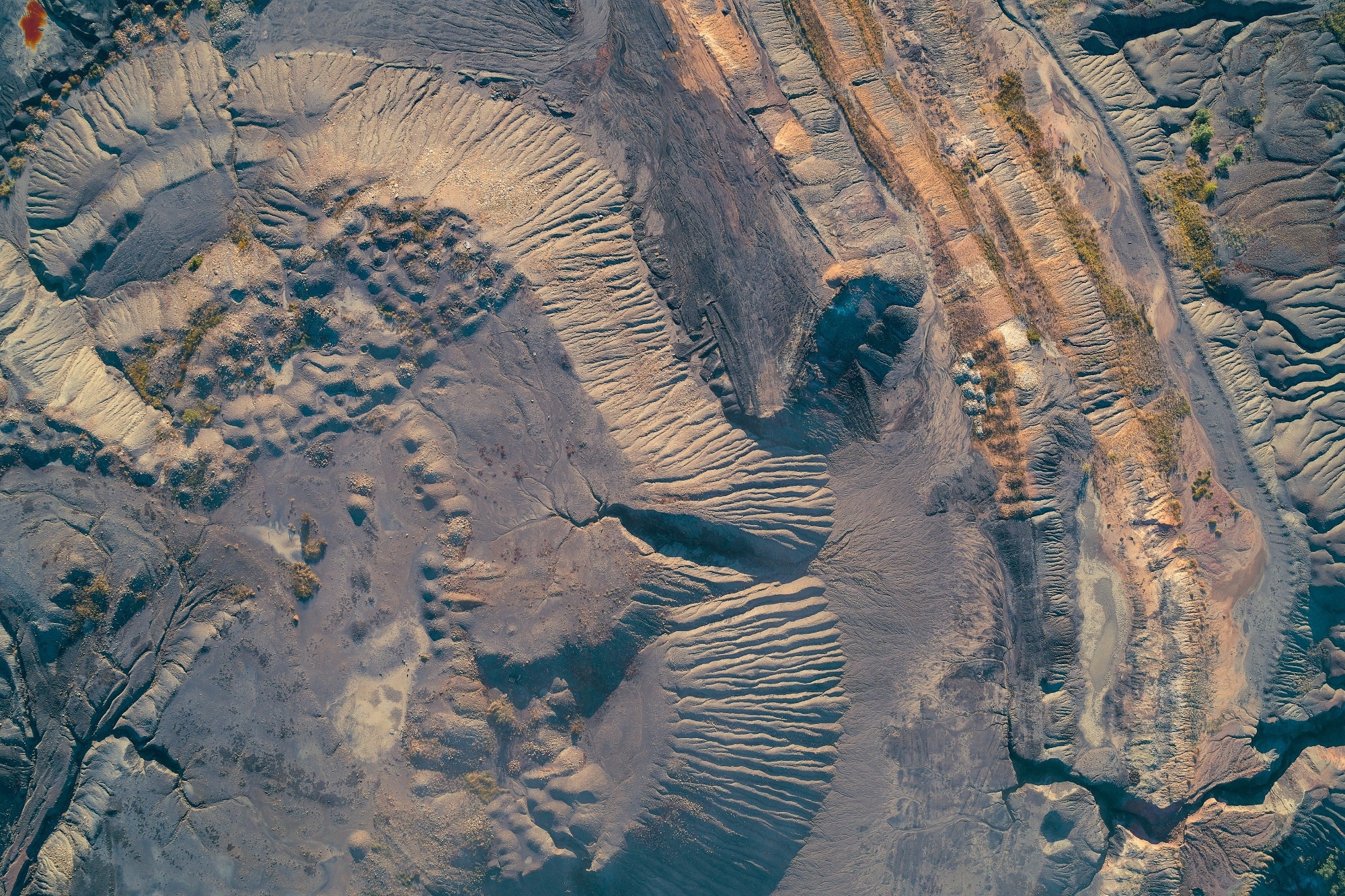

Image Credit: UrbanWitnessStock/Shutterstock.com

In response, experts around the world are working on practical solutions to tackle these challenges. Among them, TOMRA, an ore-sorting technology company, is advancing sensor-based systems designed to lower the environmental footprint of mining operations. At the same time, initiatives are finding productive uses for mining byproducts, such as repurposing waste materials for road construction.

Additional efforts focus on deploying real-time sensing technologies to monitor waste streams more accurately, alongside innovative frameworks to reduce mining waste and redirect it toward commercial applications. Collectively, these approaches seek to improve the efficiency of resource extraction while minimizing its environmental impact. Let's take a closer look.

Mining Waste and Its Significance

The extraction and processing of rare earth minerals, performed through different mining processes, generate significant amounts of waste, including topsoil burden, tailings, and waste rock. According to industrial research, mining activities worldwide lead to 13 billion tons of tailing waste annually, with experts projecting the figure to reach 2 trillion tons by 2050. The mining of copper may be responsible for 858 billion tons of tailing waste during these 25 years.1

Mining waste management is a key technology and a highly profitable industry, with its market size estimated at around 183 billion US dollars in 2023, expected to reach 234 billion US dollars by 2032.

Mining waste is important because it contains valuable, reusable resources. The resources and elements found in mining waste have been recycled and repurposed for use as construction materials, geopolymeric products, and other commercial, sustainable materials. Some mining waste also contains significant amounts of metal oxides, which have been repurposed as efficient catalysts for a variety of chemical reactions.2 This brief overview proves that mining waste is a gold mine if repurposed and recycled efficiently.

The non-economic by-products of mining activities, beneficiation, and mineral processing are referred to as mining waste. This residual material is managed by carefully storing it in proper containment facilities and is usually discharged into the surrounding environment, such as oceans and rivers.

Mining waste, in addition to the types mentioned above, may also occur in various forms, such as stripped soil, bauxite residue, metallurgical slags, partially broken coarse rock overburden, unweathered development waste rock in underground mines, and residual ores.3

The United States Environmental Protection Agency has included a few specific mining and mineral processing wastes as part of the “Special Wastes”. These include slags from primary copper and lead processing, phosphogypsum from phosphoric acid production, process wastewater from coal gasification, flurogypsum from hydrofluoric acid production, air pollution control dust/sludge from iron blast furnaces, and many other processes.4

Challenges of Mining Waste

With the constant increase in mining operations driven by rising demand for minerals across industries such as the electric vehicle (EV) industry, mining waste has grown rapidly, leading to various challenges, including its efficient management.

Over the last decade, there has been a sharp rise in long-term chronic waste issues, such as sedimentation, acid mine drainage (AMD), and seepage.5 Mining waste often contains heavy metals that lead to toxic effects that destroy the metabolism of living organisms and cause hematopoiesis, hereditary disorders, and various types of cancers. Furthermore, mining wastewater also destroys the aquatic habitat, affecting fish and water-based plants.6

These challenges highlight the importance of efficient waste management and the use of effective techniques to utilize mining waste for various commercial purposes.

Reducing Mining Waste: A Brief Overview

Experts have shifted their focus to sustainable mining operations and waste management, efficiently reducing waste generation, optimizing resource use, and ensuring safe management of mining waste.

Prominent techniques include dry stacking of tailings, bioremediation, and the implementation of circular-economy principles for managing mining waste. Dry stacking has resulted in a significant decrease in dam failure, with the use of microorganisms in bioremediation processes efficiently immobilizing and neutralizing waste products into reusable substances.

Carbon capture and storage (CCS) technology has been key to massively reducing CO2 emissions from mining operations.

Recently, advanced waste sorting and classification techniques such as sensor-based systems and artificial intelligence (AI)-based frameworks have helped identify and extract usable minerals from mining waste. This not only decreases the amount of waste generated but also significantly boosts the proportion of valuable ore, increasing profitability and cost-effectiveness.7

How are Sensors Being Used to Reduce or Eliminate Mining Waste?

The paradigm shift in sustainability and the implementation of Industry 4.0 have made modern sensors and sensing mechanisms the backbone of sustainable mining practices. Sensors are being extensively used to optimize mining operations, ensure safety, and efficiently manage mining waste.

Sensor-based sorting systems (SBS), integrating key technologies like X-ray transmission (XRT) and laser scattering with next-gen sensors, ensure efficient waste reduction and removal, ensure cost-effective ore evaluation, lower cut-off grades, and significantly improve the mine life. The technical and financial insights available due to sensing systems aid the companies in ensuring compliance with modern standards and Sustainable Development Goals (SDGs).

Sensors detect mineral content and remove waste rock, improving the ore processing efficiency and reducing the amount of waste generated. By carefully selecting ores with higher mineral content, the ecological footprint is reduced through lower energy consumption.8 Furthermore, the critical data on mineralogy, grain size, and waste management allows experts to train data-based AI models for future applications.

TOMRA: Sensor-Based Solutions for Reducing Mining Waste

TOMRA is a pioneer in sensor-based solutions and sorting technology for mining operations, optimizing the efficiency, output, and product quality.

TOMRA’s AI-Powered OBTAIN Sorting Technology

TOMRA has a cutting-edge technology called OBTAINTM that uses Deep Learning (DL) algorithms to enable the detection and accurate classification of individual ore particles. At the base of the system is a network of highly optimized neural networks that precisely analyze the properties of individual particles. It then provides insights into particle-size distribution and a complete report on the sorter's performance.9

TOMRA’S AI-Powered CONTAIN Technology

TOMRA’s AI-driven CONTAINTM technology is a game changer for the recovery of inclusion-type ore. Experts can analyze ores in a deeper, smarter, and highly technical way, enabling much greater mineral recovery. The technology involves applying DL to XRT data, revealing insights into valuable substances buried within rocks and mining waste.

The accurate detection of mineralogical patterns in ores and waste materials allows CONTAIN to precisely indicate the presence of valuable metals like tungsten, etc. The technology assigns a probability score regarding the occurrences of subsurface minerals, allowing companies to boost productivity and waste management using data-driven metrics.10

Using its key technologies, TOMRA is at the forefront of next-gen sensor-based sorting and waste recycling solutions, enabling the implementation of circular-economy principles in modern mining operations.

TOMRA’s sensor-based XRT sorting has been a game-changer at the Kensington mine in Alaska, recycling mining waste products into usable substances by recovering precious elements like gold.11 The sensor-based platform provided by TOMRA reduces the need for unnecessary processing, improving ore discrimination, enhancing recovery of minerals from processed ores, and minimizing the volume of tailings waste.

TOMRA Mining - Sorting Tomorrow's Resources

Video Credit: TOMRA/YouTube.com

Uses of Mining Waste in Road Construction

While sensor-based technologies and circular economy frameworks are reducing the volumes of mining waste, experts are also using them for viable commercial projects. A profitable avenue is the utilization of mining waste for constructing roads.

Various studies have been conducted, with waste rock and slag deemed ideal for road construction owing to their exceptional mechanical strength and durability. Fly ash and tailings are inherently pozzolanic; however, highly energy-intensive steps are needed to ensure stabilization.

The use of mining waste in road construction has proven to be key for landfill reduction, significantly reducing harmful emissions, promoting sustainability, and reducing dependence on conventional materials.12

What Does the Future Hold?

Adopting safe and sustainable mining practices, along with sensor-based waste management systems, is pushing us toward SDG-compliant mining operations. The application of a fully automated sensor-based mining operations framework, from ore scanning, identification, extraction, to waste management, is currently not even justified theoretically. However, technological innovations and modern sustainable frameworks are already pushing us into the digital era of modern mining, prioritizing resource-efficient operations and ecological protection.

References and Further Reading

- Hudson-Edwards, K. et al. (2024). Tailings storage facilities, failures and disaster risk. Nature Reviews Earth & Environment. 5(9). 612-630. Available at: https://doi.org/10.1038/s43017-024-00576-4

- Abbadi, A., & Mucsi, G. (2024). A review on complex utilization of mine tailings: Recovery of rare earth elements and residue valorization. Journal of Environmental Chemical Engineering, 12(3), 113118. Available at: https://doi.org/10.1016/j.jece.2024.113118

- Vallero, D. A., & Blight, G. (2019, January). Mine waste: A brief overview of origins, quantities, and methods of storage. Waste (pp. 129-151). Academic Press. Available at: https://doi.org/10.1016/B978-0-12-815060-3.00006-2

- United States Environmental Protection Agency (USEPA) (Updated: 2025). Special Wastes. [online] Available at: https://www.epa.gov/hw/special-wastes#mining. [Accessed on: February 13, 2026].

- Vivoda, V. et al. (2025). Geopolitics and mine waste: An overview and future research directions. Journal of Environmental Management, 385, 125545. Available at: https://doi.org/10.1016/j.jenvman.2025.125545

- Zabaikin, I. et al. (2022). Disposal of mining waste and its impact on the environment. Ecological Engineering & Environmental Technology, 23. Available at: https://doi.org/10.12912/27197050/147142

- Gairola, S. et al. (2025). Sustainable mining: reducing waste and enhancing resource efficiency. Discov Civ Eng 2. 75. Available at: https://doi.org/10.1007/s44290-025-00233-9

- Saskatchewan Research Council, Canada (Src.sk.ca). (2019). Sensor-Based Sorting | Saskatchewan Research Council. [online] Available at: https://www.src.sk.ca/services/sensor-based-sorting. [Accessed on: February 15, 2026].

- Tomra.com. (2024). OBTAIN(TM) AI Ore Sorting Technology. (online). Available at: https://www.tomra.com/mining/products/technologies/obtain [Accessed 16 Feb. 2026].

- Tomra.com. (2024). CONTAIN(TM) Deep Learning Ore Classification. [online] Available at: https://www.tomra.com/mining/products/technologies/contain [Accessed 17 Feb. 2026].

- McMillan, A. (2026). TOMRA: Turning Mining Waste into Connected Infrastructure. [online] Constructiondigital.com. Available at: https://constructiondigital.com/news/tomra-mining-waste-connected-infrastructure [Accessed 18 Feb. 2026].

- Mashaan, N., & Yogi, B. (2025). Mining waste materials in road construction. Encyclopedia, 5(2), 83. Available at: https://doi.org/10.3390/encyclopedia5020083

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.