Axcap Ventures Inc. ("Axcap") is pleased to announce results from the first hole, CV25-001C, in its ongoing 5,500-meter drill program at the Converse Project, located in the Battle Mountain-Eureka Trend, Nevada.

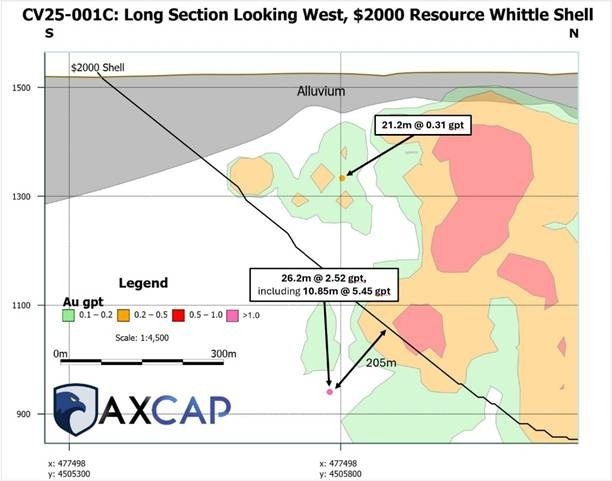

Figure 1. Long-Section Through Converse - Looking West. Image Credit: Axcap Ventures Inc

Figure 1. Long-Section Through Converse - Looking West. Image Credit: Axcap Ventures Inc

Highlights

- The first hole from Axcap's maiden drill campaign, CV25-001C, has confirmed modelled near-surface gold mineralization but has intersected a potentially new zone of higher-grade mineralization at depth.

- The 10.85 m at 5.45 g/t in Axcap's first ever drillhole demonstrates a new component of mineralization that has not been explored or modelled by prior operators. Full Details of the intersection can be found in Table 1 and 2.

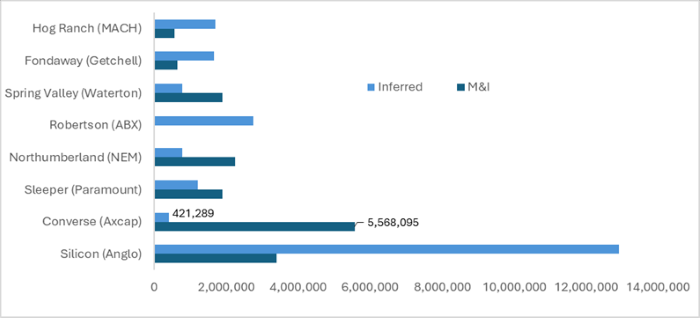

- The Converse project already hosts a large open pit resource containing 5.5 Moz mineral resource at 0.53 g/t in the measured and indicated categories and 420 koz at 0.53 g/t in the inferred category (run at a gold price of US$2,000/oz) (for more information see the Technical Report - https://www.sedarplus.ca/csaparty/records/document.html?id=f5fc799144448597be7850499f79385bbb7bdd3a8ced42847e6c2ffe92bea62a )

Key Results from CV25-001 Include:

- 26.18 meters grading 2.52 g/t gold from 654 meters depth, including a core intersection of 10.85 meters grading 5.45 g/t gold from 666.4 meters. (Figure 1, Table 3)

- 21.21 meters grading 0.31 g/t Au, 9.71 g/t Ag and 0.18% Cu starting from 208.8 m supporting and potentially expanding the current open pit resource. (Table 2)

Details

- The drill hole is hosted in retrograde skarn altered limey sandstone, containing abundant sulphide minerals.

- Recall that the 2025 drill program was designed to confirm the current open-pit resource estimate (described above), reduce the internal waste and strip ratio, and importantly, test for mineralization both below and adjacent to the current pit shell, where it remains open for expansion.

- Axcap is currently awaiting results for the balance of CV25-001C as well as CV25-002C, the later hole targeted mid-plate rocks, below the Golconda Thrust , for the first time at Converse. These mid-plate rocks are known to host ore zones in mines flanking the Buffalo Valley.

Blake McLaughlin, VP Exploration, stated: " This intersection significantly expands the mineralized area at Converse and validates our exploration approach. The high-grade interval clearly demonstrates the potential for meaningful discoveries of new sub-sets of higher-grade mineralization within these favorable rock units. We anticipate continued positive results from our ongoing drilling program throughout the summer."

Figure 2. Converse Is Already A Large Nevada Resource (Contained Gold Oz). Image Credit: S&P Capital IQ, Converse 2025 MRE was calculated using the costs and values of $2000 au, $2.00/t mined mining cost, $4.50/t processed processing cost, $1.00/t processed G&A, $2.50/oz refining, 77%/62%/50% recoveries for oxide/transition/sulphide respectively, 6% NSR, slope angles used range from 36-41 degrees

Table 1. Drill Hole Parameters. Source: Axcap Ventures Inc

| HoleNo |

Coordinate

System |

Easting |

Northing |

Elevation |

Azimuth |

Dip |

Depth

(m) |

| CV25-001C |

NAD 83

UTM Zone 11 |

477,333 |

4,505,813 |

1,518 |

96 |

-56 |

701 |

Table 2. Upper Interval in CV25-001C with 21.21 meters grading 0.31 g/t Au, 9.71 g/t Ag and 0.18% Cu. Source: Axcap Ventures Inc

| From (m) |

To (m) |

Sample

Designation |

Au Final

(ppm) |

Ag Final

(ppm) |

Cu Final

(ppm) |

| 208.8 |

209.4 |

K730917 |

1.115 |

39.6 |

6630 |

| 209.4 |

210.0 |

K730918 |

0.111 |

1.3 |

277 |

| 210.0 |

210.8 |

K730919 |

0.061 |

0.3 |

103 |

| 210.8 |

211.1 |

K730921 |

0.034 |

1.0 |

139 |

| 211.1 |

212.0 |

K730922 |

0.203 |

0.7 |

61 |

| 212.0 |

212.6 |

K730923 |

0.068 |

3.6 |

581 |

| 212.6 |

213.2 |

K730924 |

0.051 |

0.6 |

76 |

| 213.2 |

213.6 |

K730925 |

1.165 |

3.6 |

67 |

| 213.6 |

215.2 |

K730926 |

0.023 |

0.3 |

75 |

| 215.2 |

215.9 |

K730927 |

0.019 |

0.7 |

130 |

| 215.9 |

216.4 |

K730928 |

0.323 |

18.6 |

3590 |

| 216.4 |

217.2 |

K730929 |

0.076 |

1.9 |

323 |

| 217.2 |

217.5 |

K730931 |

0.130 |

4.7 |

612 |

| 217.5 |

218.0 |

K730932 |

1.770 |

101.0 |

17500 |

| 218.0 |

218.7 |

K730933 |

0.277 |

10.1 |

2380 |

| 218.7 |

219.6 |

K730934 |

0.161 |

1.1 |

178 |

| 219.6 |

220.7 |

K730935 |

0.050 |

1.3 |

195 |

| 220.7 |

221.7 |

K730936 |

0.207 |

0.9 |

111 |

| 221.7 |

222.0 |

K730937 |

2.990 |

144.0 |

28600 |

| 222.0 |

222.3 |

K730938 |

0.136 |

5.2 |

959 |

| 222.3 |

223.1 |

K730939 |

0.022 |

1.3 |

179 |

| 223.1 |

223.4 |

K730941 |

3.180 |

67.4 |

13550 |

| 223.4 |

224.7 |

K730942 |

0.074 |

1.5 |

170 |

| 224.7 |

225.3 |

K730943 |

0.087 |

3.1 |

510 |

| 225.3 |

225.9 |

K730944 |

0.226 |

38.5 |

7210 |

| 225.9 |

226.3 |

K730945 |

0.268 |

7.3 |

1355 |

| 226.3 |

227.1 |

K730946 |

0.534 |

6.1 |

583 |

| 227. |

227.4 |

K730947 |

0.078 |

2.1 |

380 |

| 227.4 |

228.8 |

K730948 |

0.101 |

1.2 |

110 |

| 228.8 |

229.3 |

K730949 |

0.111 |

0.3 |

99 |

| 229.3 |

230.0 |

K730951 |

0.255 |

0.3 |

75 |

Table 3. Full Assays for New Zone Below Current Resource in CV25-001C. Source: Axcap Ventures Inc

| From (m) |

To (m) |

Sample

Designation |

Au Final

(ppm) |

Ag Final

(ppm) |

Cu Final

(ppm) |

| 654.1 |

655.6 |

K731361 |

0.254 |

0.3 |

13 |

| 655.6 |

656.7 |

K731362 |

0.113 |

0.3 |

12 |

| 656.7 |

658.1 |

K731363 |

0.433 |

0.3 |

33 |

| 658.1 |

659.4 |

K731364 |

0.227 |

0.3 |

26 |

| 659.4 |

660.8 |

K731365 |

1.780 |

0.3 |

74 |

| 660.8 |

661.7 |

K731366 |

0.729 |

0.3 |

34 |

| 661.7 |

662.6 |

K731367 |

0.197 |

0.6 |

193 |

| 662.6 |

663.2 |

K731368 |

0.202 |

2.8 |

898 |

| 663.2 |

664.3 |

K731369 |

0.034 |

0.3 |

161 |

| 664.3 |

665.7 |

K731371 |

0.407 |

0.3 |

53 |

| 665.7 |

666.4 |

K731372 |

0.157 |

2.2 |

605 |

| 666.4 |

667.1 |

K731373 |

2.510 |

18.0 |

5880 |

| 667.1 |

667.9 |

K731374 |

2.330 |

1.4 |

369 |

| 667.9 |

669.0 |

K731375 |

30.500* |

3.3 |

241 |

| 669.0 |

670.1 |

K731376 |

3.050 |

0.9 |

318 |

| 670.1 |

671.1 |

K731377 |

1.165 |

1.2 |

318 |

| 671.1 |

671.8 |

K731378 |

0.286 |

0.3 |

78 |

| 671.8 |

672.8 |

K731379 |

0.188 |

0.3 |

139 |

| 672.8 |

674.2 |

K731381 |

0.456 |

0.3 |

67 |

| 674.2 |

675.7 |

K731382 |

8.230 |

1.5 |

120 |

| 675.7 |

677.3 |

K731383 |

3.190 |

1.3 |

301 |

| 677.3 |

678.8 |

K731384 |

0.528 |

0.3 |

88 |

| 678.8 |

680.3 |

K731385 |

0.352 |

0.9 |

246 |

*Metallic Screen pending for >10 g/t sample overlimit trigger procedure

Quality Control & Quality Assurance

Drill holes are either collared with a PQ drill bit or pre-collared with an RC rig through overburden. Holes are reduced to HQ as the drill hole progresses into deeper more competent ground. Drill core produced by coring drill rigs is hydraulically extracted from the core tubes by the drill contractor, marked for consistent orientation and placed in core boxes with appropriate depth markers added. Full core boxes are then sealed before being transported by Axcap personnel to the Carlin Coreshack. Core is processed, geologically and geotechnically logged, checked for recovery, photographed, and marked for specific gravity, geotechnical studies and for assays. The core is cut in half onsite at the Coreshack, half-core is placed in plastic bags, zip-tied and grouped in burlap sacks and sealed for transport to the ALS Global sample preparation facility in Elko, Nevada. Sample preparation is done according to ALS Global code PREP-31Y. Once samples are prepared, ALS Global internally ships the samples to their assay laboratory in Reno, Nevada. The primary assay methods used are ALS Global codes Au-AA23 and ME-ICP61. The gold overlimit methods are Au-GRA21 and Au-SCR21 (overlimit triggers are 3 ppm and 10 ppm respectively). ALS Global is an independent, ISO-accredited laboratory with no affiliation to Axcap Ventures beyond its role as a third-party analytical service provider. The retained half-core is stored in a fenced-in yard until transported to the company's warehouse in Lovelock, Nevada.

QA/QC is performed as each certificate is imported into Axcap's GeoSequel database. Performance charts are prepared for coarse blanks and all certified reference material used. Axcap uses OREAS standards for the Converse project. Performance charts are also reviewed regarding ALS lab prep and pulp duplicates on Webtrieve to identify potential analytical issues with coarse gold. Coarse blank above 10x over the lower detection limit (LDL) of the Au-AA23 method are re-run.

For certified reference materials, the certified mean is considered the target. The certified standard deviation is used to calculate the acceptable range. The acceptable range is defined as within 3 standard deviations from the certified mean.

Qualified Person

Mr. Blake Mclaughlin, P.Geo., registered with the Professional Geoscientists Ontario, is the Company's Vice President of Exploration and a Qualified Person, as defined by National Instrument 43-101 - Standards for Disclosure for Mineral Projects. Mr. Mclaughlin has verified the data through site visits, inspection of drill core, review of original assay certificates, and confirmation of QA/QC protocols. No limitations were encountered during the verification process, and the data is considered reliable for the purposes of this disclosure.