Reviewed by Frances BriggsJan 23 2026

Researchers from Columbia Engineering have developed a novel technique for lithium extraction that has the potential to significantly reduce processing times, access reserves that current methods cannot utilize, and lessen environmental harm.

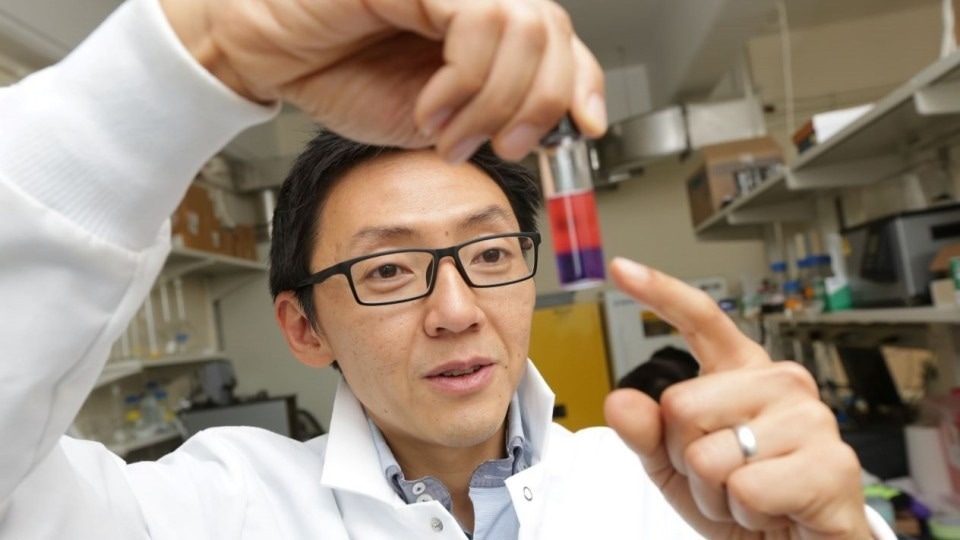

Image Credit: Columbia Engineering

Image Credit: Columbia Engineering

The demand for lithium is surging as factories worldwide produce electric vehicles and the large batteries that ensure wind turbines and solar panels serve as dependable energy sources.

However, existing methods for lithium production are sluggish and depend on high-quality feedstocks that are available in only a limited number of locations globally. On top of this, the environmental repercussions are considerable: the refinement of this mineral, essential for clean energy, necessitates extensive land use and contaminates water supplies relied upon by local communities.

The new method employs a temperature-sensitive solvent to extract lithium directly from brines located in deposits around the globe. In contrast to existing technologies, this technique can effectively extract lithium even when it is present in very low concentrations and mixed with similar substances. The study was published in Joule.

The study indicates that this innovation, termed switchable solvent selective extraction, or S3E (pronounced S three E), can extract lithium with remarkable selectivity: up to 10 times greater than sodium and 12 times greater than potassium.

The process effectively eliminates magnesium, a frequent contaminant in lithium brines, by initiating a chemical precipitation step that separates it.

Improving on Solar Evaporation

Approximately 40 % of lithium production originates from a saline brine located in extensive reservoirs beneath desert landscapes.

Almost all of this lithium is obtained through a method known as solar evaporation, in which the brine is transferred into expansive ponds that are heated by the desert sun – for a duration of up to two years – until a sufficient amount of water has evaporated.

This process is only practical in arid, level areas with significant land availability, such as the Atacama Desert in Chile or certain regions of Nevada. Additionally, it requires substantial quantities of water in locations that can barely sustain such usage.

There’s no way solar evaporation alone can match future demand. And there are promising lithium-rich brines, like those in California’s Salton Sea, where this method simply can’t be used at all.

Ngai Yin Yip, La Von Duddleson Krumb Associate Professor, Earth and Environmental Engineering, Columbia University

In contrast to traditional lithium recovery techniques, S3E does not depend on binding chemicals or elaborate postprocessing. Rather, the method takes advantage of the interaction between lithium ions and water molecules within a solvent system that alters its properties according to temperature.

At ambient temperature, the solvent extracts lithium and water from the brine. Upon heating, it discharges the lithium, together with water, into a purified stream and regenerates itself for subsequent use.

An Approach with Tremendous Potential

In laboratory experiments using synthetic brines that replicate the conditions of the Salton Sea, a geothermal area in Southern California believed to contain sufficient lithium to power over 375 million electric vehicle batteries, the system successfully extracted almost 40 % of the lithium after only 4 cycles with the same solvent batch. This indicates a promising approach for achieving continuous operation.

This is a new way to do direct lithium extraction. It’s fast, selective, and easy to scale. And it can be powered by low-grade heat from waste sources or solar collectors.

Ngai Yin Yip, La Von Duddleson Krumb Associate Professor, Earth and Environmental Engineering, Columbia University

The team highlighted that this is a proof-of-concept study. The system has not yet been optimized for yield or efficiency. However, even in its initial form, S3E seems sufficiently promising to serve as an alternative to evaporation ponds and hard-rock mining, the two predominant methods in the lithium supply chain today and both of which entail significant trade-offs.

As the global transition to clean energy accelerates, technologies such as S3E could be instrumental in maintaining momentum by enabling the extraction of lithium more rapidly, cleanly, and from a wider range of locations than ever before.

We talk about green energy all the time. But we rarely talk about how dirty some of the supply chains are. If we want a truly sustainable transition, we need cleaner ways to get the materials it depends on. This is one step in that direction.

Ngai Yin Yip, La Von Duddleson Krumb Associate Professor, Earth and Environmental Engineering, Columbia University

The study was supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences. Additional support was provided by the National Science Foundation Graduate Research Fellowship.

Journal Reference:

Dach, E., et al. (2026) A novel approach for direct lithium extraction from alkali metal cations in brine mixtures using thermally switchable solvents. DOI: 10.1016/j.joule.2025.102265. https://www.sciencedirect.com/science/article/abs/pii/S2542435125004465